27motorhead

Old School Grand Master

- Feedback

- View

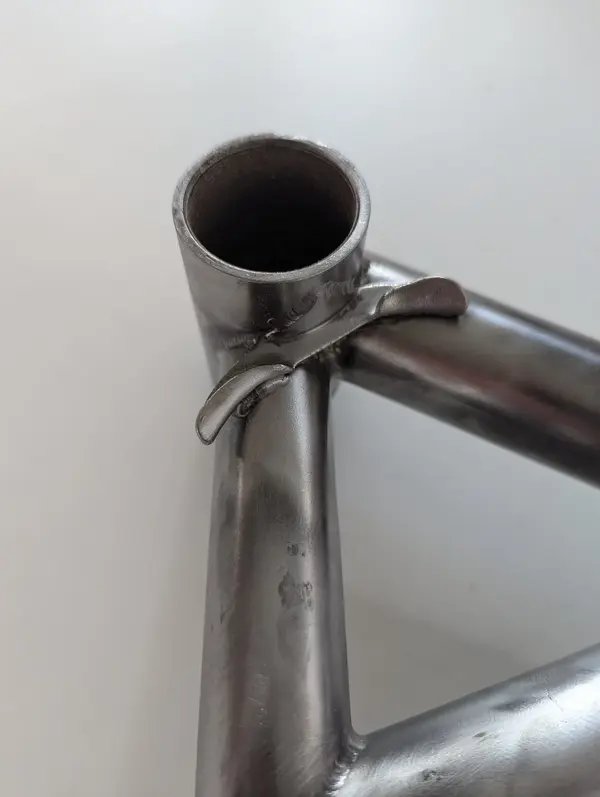

The best was to remove a fixed cup with leverage is this method below. I don't have to write anything because @rmwesley kindly created this thread!

https://www.retrobike.co.uk/threads/fixed-cup-removal-with-pics.456107/

Have used this many a time on fixed cups on old Raleigh Choppers from the 70s.

If you are having frame repaired due to corrosion then heat will certainly help remove it.

For cutting it out, carbide tipped hacksaw blade, die grinder, Dremel are all methods of attack. I suspect the stud & nut method will work if you can find a decent long leverage bar and are able to clamp the frame securely without damaging it in the process!

Amazed the seatpost came out as it did. Well done on that one!!!

Keep up the great work!

https://www.retrobike.co.uk/threads/fixed-cup-removal-with-pics.456107/

Have used this many a time on fixed cups on old Raleigh Choppers from the 70s.

If you are having frame repaired due to corrosion then heat will certainly help remove it.

For cutting it out, carbide tipped hacksaw blade, die grinder, Dremel are all methods of attack. I suspect the stud & nut method will work if you can find a decent long leverage bar and are able to clamp the frame securely without damaging it in the process!

Amazed the seatpost came out as it did. Well done on that one!!!

Keep up the great work!