This takes less than 5 minutes, admire my Karakoram if you wish.

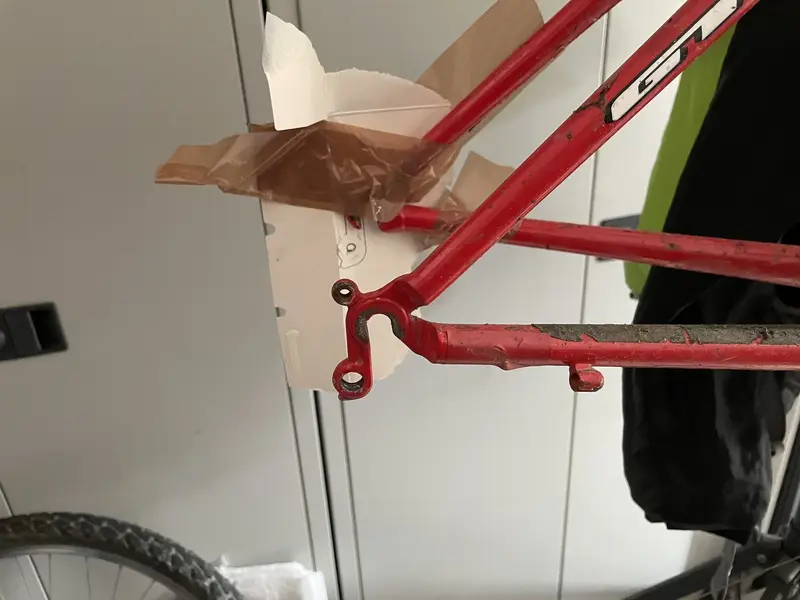

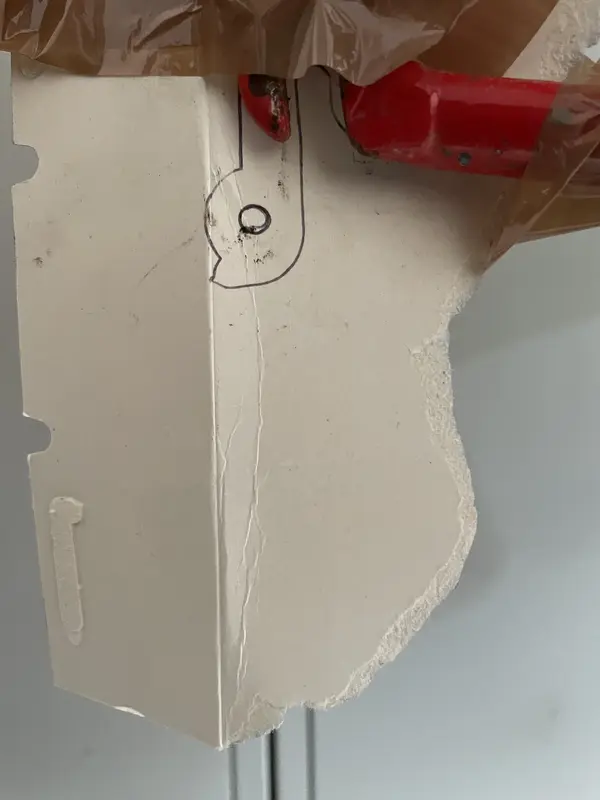

Remove rear wheel, skewer and mecRip piece of card off cereal box. I've used Shreddies. Trace r/h dropout onto card. Attach to l/h dropout.

Screw axle into mech hanger from behind. Putting the wheel wrong way gives you something to put fingers/spa

Push skewer in.

Look where skewer touches card. Bull

A quick bonus photo, probably should be in the same colour thre

Thanks, that is a nice alternative idea.

Well I have just finished up doing it myself with my self made tool. Tool only took about 10-15 minutes to create from bits in the garage.

Had a box of nuts/bolts. Not much metal around but plenty of wood off cuts. Now of course wood is more likely to get indented under force, and in turn lose accuracy for further readings, if you try and bend the hanger with it but I only used it as a guide to take the readings with a measurer.

Didn't have a bolt that was just the right fit for hanger thread so I got a close one and found two nuts, one for either side to hold it fast and a third to hold the wood fast. Took a couple of pictures but not uploaded.

I drilled a hole in the wood for the bolt and used the one nut to fasten that then checked with a set square and happily it was bang on first try even though I drilled the hole manually and had expected perhaps some trial and error.

Bit of a fiddle to get it on and off the hanger considering it is very close to the cassette but managed by taking the wheel on and off in between readings. I could have eased this by switching the wheel around but had already started measuring when I thought of that so just carried on.

So...as to how it worked. Fantastically if I do say so myself!

Here are the readings, using the tube barrel hole on the wheel each time as advised in one of the videos:

before:

top: 7.2cm

bottom: 11.7cm

after:

top: 9.4cm

bottom: 10cm

I did it slow and steady, put it on, measure, do an adjustment with the mole grips, measure again. After the first couple of times I got a feel for how much I could expect it to alter it. From the first reading I did a calculation that I was aiming for 9.45cm top and bottom (7.2+11.7=18.9/2=9.45). Due to the slight offset from center of the hanger I thought that could factor into things and I thought the after readings to be a pretty good result!

So the moment of truth...I put the wheel back on and to my delight the issues with the clattering are gone. It looks to be much straighter now both on the smallest and the biggest cogs. However, the indexing issues appear little changed. I am thus glad to rule this out and feel confident it is just a case of compatibility.

I could try a hanger extender, which I am going to buy anyway I think just for the other clearance issues, but I don't expect that to be the indexing fault given that if that were so the smaller cogs would index fine.

Thanks to those helpful posts which aided me in the remedy for that larger (self imposed) issue! Regardless it was a very fun and satisfying exercise and I am sure a valuable skill for future!