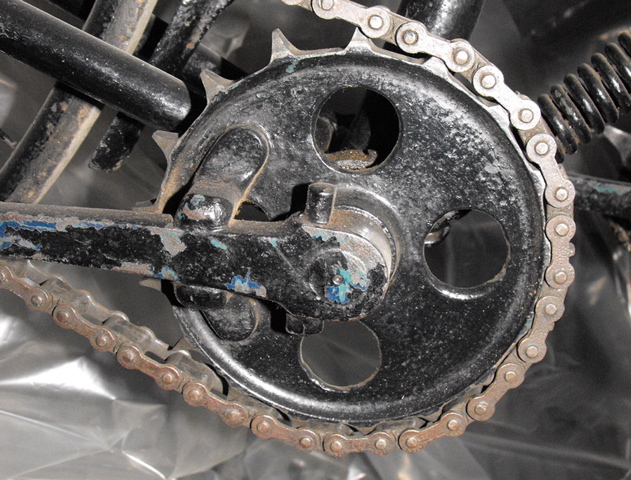

I have quite a few photos of the Whippet sitting in the Ottawa Museum of Science and Technology. It's under plastic, sitting up in a mezzanine, and not on display. I do not, however, have one photo that shows an entire crank arm. So, here is the lower section, held to the BB axle with a tapered cotter pin >

The top of the crank arm featured an adjustable slot for different crank lengths. Isn't that perfect for a cyclist that has one leg longer than the other?

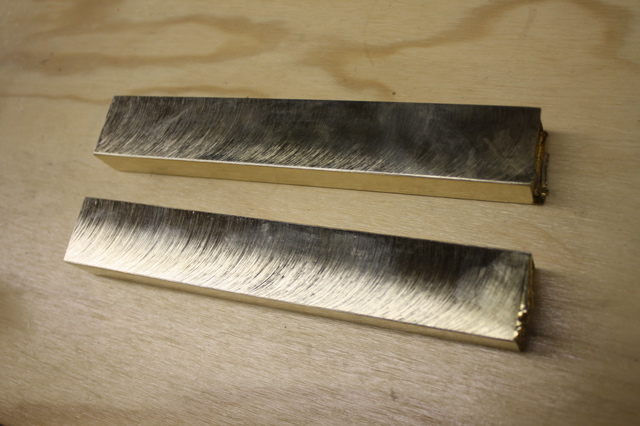

The starting point was a bar of 954 bronze that cost me $100 several years ago. 954 bronze has a higher tensile strength than 4130; perfect for strong crank arms >

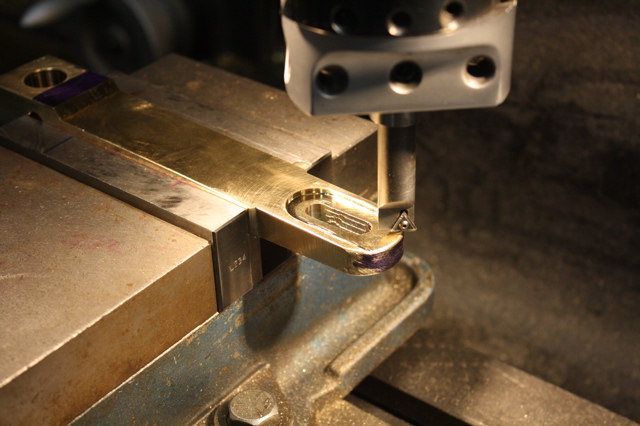

There was a bit of extra material, so that got milled off >

Machinist blue for layout, as usual. Critical holes have been drilled / bored. Now it's just a matter of getting the shape right >

A facemill was used to make a very slight taper from top to bottom >

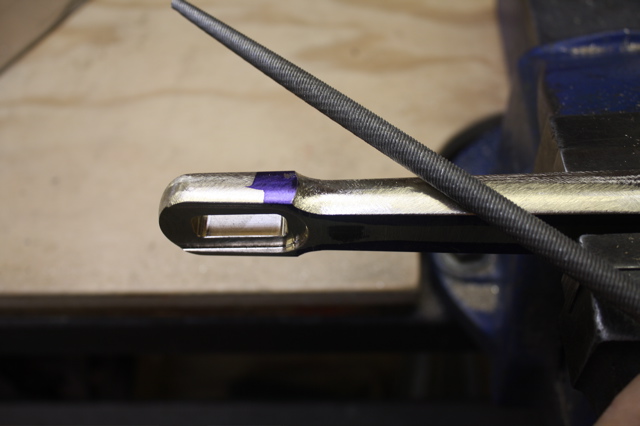

The sides were still parallel, so it was easy to hold the arm in the mill vise and slot for the pedals >

A carbide insert in a Boring Head was used to mill a flat for the washer and pedal nut to tighten against >

See the arc scribed in the (lower) machinist blue? We need to machine a radius very close to that line >

A large endmill is used to do that. See how one crank arm is held in each side of the vise? This keeps the vise jaw even and square >

Now the sides are milled at a slight angle. See how the crank end is C-clamped to a right angle plate? This stops vibration and tool "chatter" >

The crank arms are taking shape, but the top and bottom surfaces would be better with a slight radius, I think >

This is my porting tool. You can see the electric motor in the background, and the hand grinder up close with a carbide burr. A cable connects the two, and a foot pedal (not shown..) controls the speed. The speed is not that high. This (great) tool is now being used to radius the top and bottom >

A hand file is used in the corners for blending >

Back into the rotary table for machining the radius around the BB axle. I don't know if Whippets really had bronze crank arms, but why not? The late 1800's were a time of great bicycle (and tricycle) experimentation, and bronze was used in other cycle parts, such as hubs. I enjoyed making these crank arms, and they polished up quite well >

>

Done!

Thanks for taking this mini tour of my shop. I hope you enjoyed it. See you @ NAHBS..

Paul Brodie