You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fixing a Victorian

- Thread starter Nabeaquam

- Start date

Nabeaquam

BoTM Winner

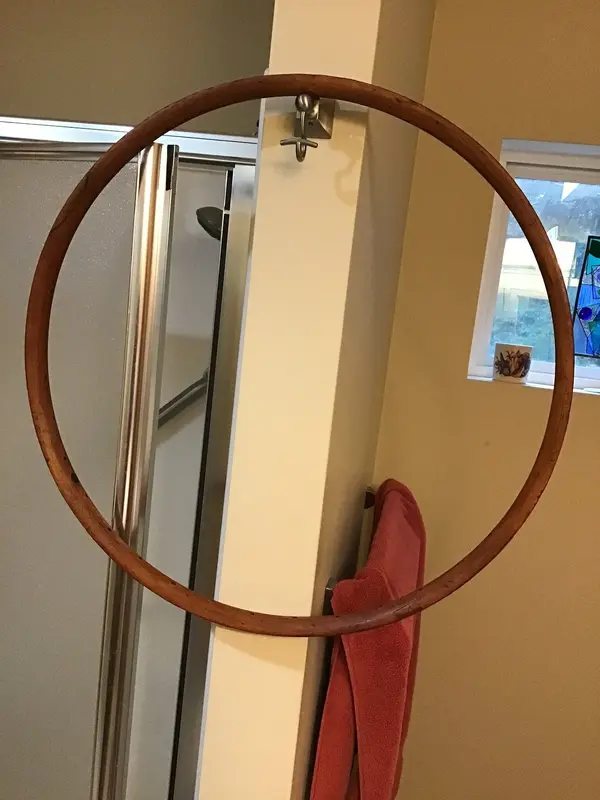

The joint expanded a little so it was sanded flush. Joint movement, usually a separation outward is common on old wood rims. My go to method is to drill through the joint and put in a slightly tight pin. After it’s stained I’ll trim the pin and epoxy it in place. So far this has always worked. This is the fourth wood rim I’ve fixed like this. If they are newer from the 1930s and have no joint movement I leave them be. I only do this in desperation. Sometimes you have to force and rub in flexible marine epoxy if there is a little total separation, then clamp then the pin. I think I once used a ratcheting tie down around the diameter and clamps to get it together after I epoxied the joint. This joint is still tight but there was a hit right on the joint that broke off a small part of the joint near the tire and moved the opposites side of the joint slightly outward. It will probably be somewhat potato chipped out when all is done. You can see the joint chip in the first and last photo. The inside of the rim still requires me to chip out the old tire glue. The last 10% of the glue that remains is the most stubborn.

Last edited:

jim haseltine

Senior Retro Guru

Back in the early 80s when I worked in the trade, the quality of Cyclo tools I saw had degraded to a pretty low point so when I saw them appear on websites I'd assumed that over the last 40 years the trade mark had been asset-stripped which made me a bit wary so I had decided to buy a Hozan, especially as I'd used a Hozan truing stand back in the day. Then by chance I came across a hardly used Cyclo threader in a charity shop so took a punt on it. The quality was good - excellent in fact, which surprised me so I did a bit of Googling. No, the company hadn't been stripped, the owning group had taken a massive risk, invested in a new factory and expanded the range.

I've probably threaded a couple of hundred spokes over the last year or so with my roller and can't see any wear on it. I tend to work on spokes in the evening while watching tv.

I've probably threaded a couple of hundred spokes over the last year or so with my roller and can't see any wear on it. I tend to work on spokes in the evening while watching tv.

Nabeaquam

BoTM Winner

Thanks for that.Back in the early 80s when I worked in the trade, the quality of Cyclo tools I saw had degraded to a pretty low point so when I saw them appear on websites I'd assumed that over the last 40 years the trade mark had been asset-stripped which made me a bit wary so I had decided to buy a Hozan, especially as I'd used a Hozan truing stand back in the day. Then by chance I came across a hardly used Cyclo threader in a charity shop so took a punt on it. The quality was good - excellent in fact, which surprised me so I did a bit of Googling. No, the company hadn't been stripped, the owning group had taken a massive risk, invested in a new factory and expanded the range.

I've probably threaded a couple of hundred spokes over the last year or so with my roller and can't see any wear on it. I tend to work on spokes in the evening while watching tv.

Nabeaquam

BoTM Winner

The hub has leather seals, just like the bottom bracket. The leather seal in the drive side, where the spring clip bearing retainer is bent has a missing leather seal. New bearings next.

The wheel has been stained light pine. I didn’t want to use any of my darker stains until I tried the lightest one. The rim was originally stained dark with red in it. I think this is good enough.

The wheel has been stained light pine. I didn’t want to use any of my darker stains until I tried the lightest one. The rim was originally stained dark with red in it. I think this is good enough.

Last edited:

Nabeaquam

BoTM Winner

Ok, the wheel has a crack where the joint was hit and moved. The pin should work as a reinforcement here.

I tried several of my stains on hardwood blocks. You have to be careful staining wood rims, otherwise you will end out too dark. Easy to mess up the stain. I used Gunstock penetrating oil stain over the light pine stain. It’s closer to the original color now.

I tried several of my stains on hardwood blocks. You have to be careful staining wood rims, otherwise you will end out too dark. Easy to mess up the stain. I used Gunstock penetrating oil stain over the light pine stain. It’s closer to the original color now.

Nabeaquam

BoTM Winner

Hyssop Brothers and Fairbanks made their rims out of cross laminated hard maple glued under hydraulic pressure. I don’t know about the other early American wood wheel manufactures. Our elms are all gone, vanished in the 1970s from Dutch elm disease. There were mammoth ones in cities.I believe most US bike rims around 1900 were elm. Here in UK our best wood rims were American maple, made with 4 laminations, and made in Paris. Around 16 ounces, and nearly indestructible.

No shrinkage, no need to retighten spokes.

Keith

Nabeaquam

BoTM Winner

I put tung oil on the wood. It needs to dry for two more days before I put on the clear top coat. I’m going to try flexible marine epoxy. I want to see if it turns too yellow. That takes two days to fully cure. If it’s good and no too yellow or dark I’ll finish my other two new raw wood rims with gunstock stain, tung oil and epoxy. My spokes aren’t here yet so its perfect timing. The rear hub had a dent in drive side dust cap, which I tapped out with a tack hammer. I also straightened the bent ball bearing retainer. I made new leather dust seals, making a pattern using the bearing retainers and a light dusting of spray paint. The rear stays are used in place of jam nuts and the races tend to get loose or tight. Needs attention every few outings, but it’s original. The front wheel didn’t have a tire and maybe this is why the spokes are rustier than the rear was. It’s still soaking in penetrant, still with stuck spokes. The local bike shop hangs old rusty spoked wood wheels overhead and soaks them periodically throughout the winter. I’m not that patient.

Similar threads

- Replies

- 7

- Views

- 201

- Replies

- 9

- Views

- 2K

- Replies

- 14

- Views

- 1K

- Replies

- 4

- Views

- 1K