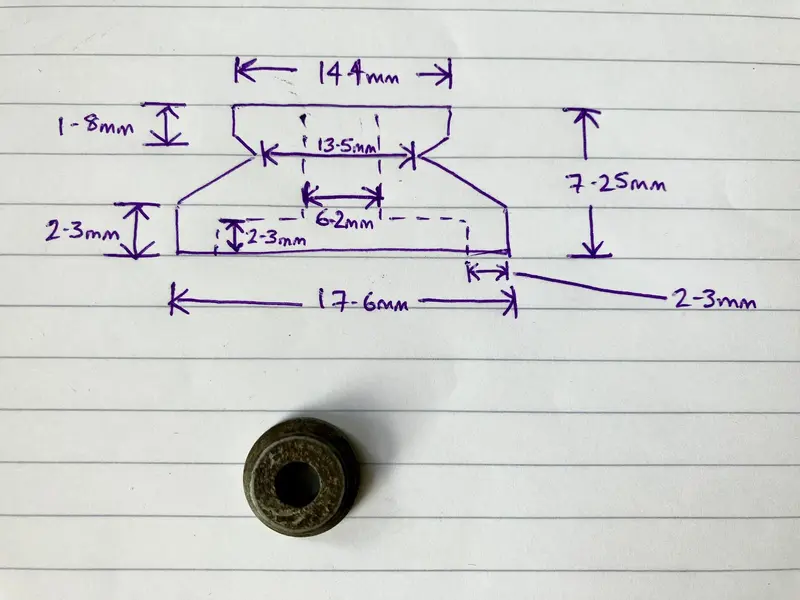

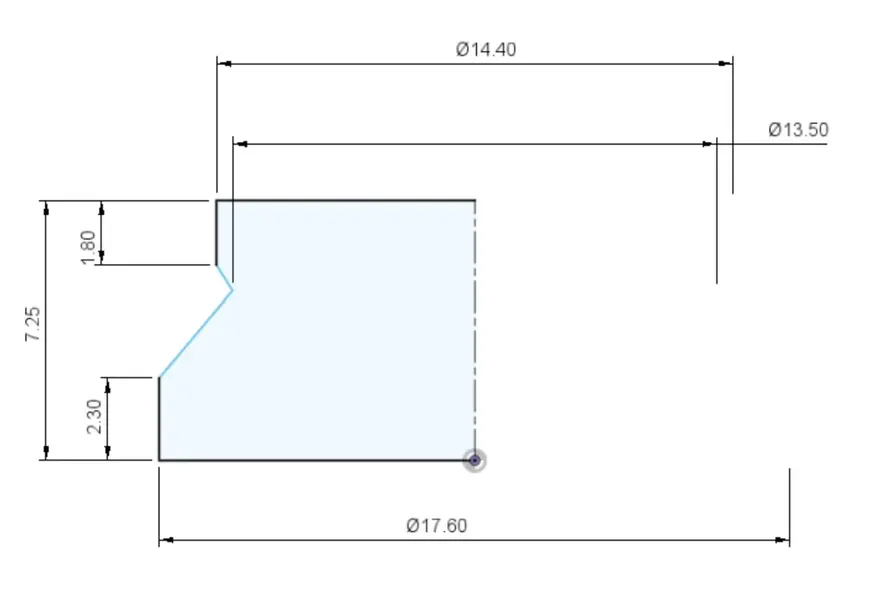

With the main components of the wheel sorted, I was eager to get the spokes organised. Using my cousin’s tool to find the ERD, and then with DT’s spoke calculator we soon established the optimum spoke lengths for a traditional cross 3 pattern.

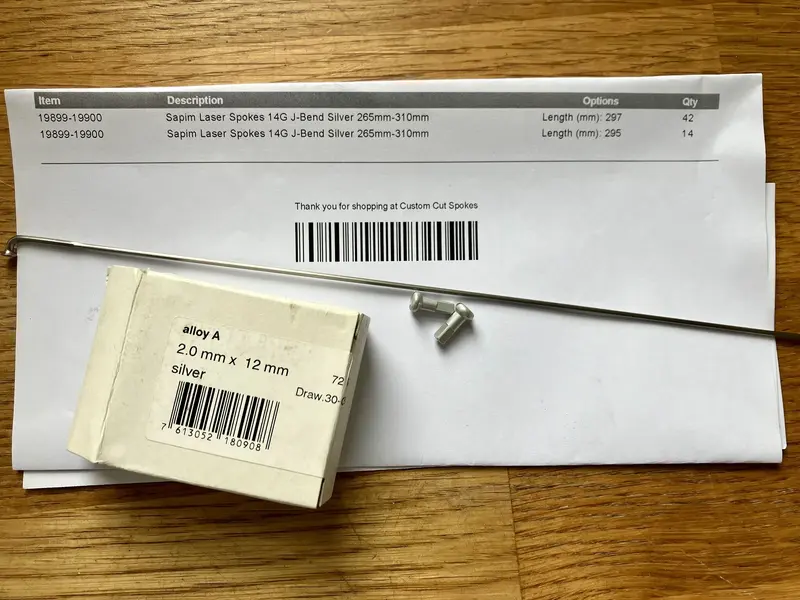

I had planned on using either DT Revoltion or Sapim Laser spokes as they’re essentially the same as each other, and the best balance of weight and strength. As the Sapim are more widely available and significantly cheaper, it was an easy choice. They came in at 83p a spoke, and I’ll be using standard 12mm DT alloy nipples to help keep the weight down. I know what people say about alloy nipples, but providing you’re using quality nipples, and liberal amounts of copper grease when building them you’ll never see a problem. I’ve run them for years without issue. Plus, this bike isn’t going to see the rigours of our winter roads!

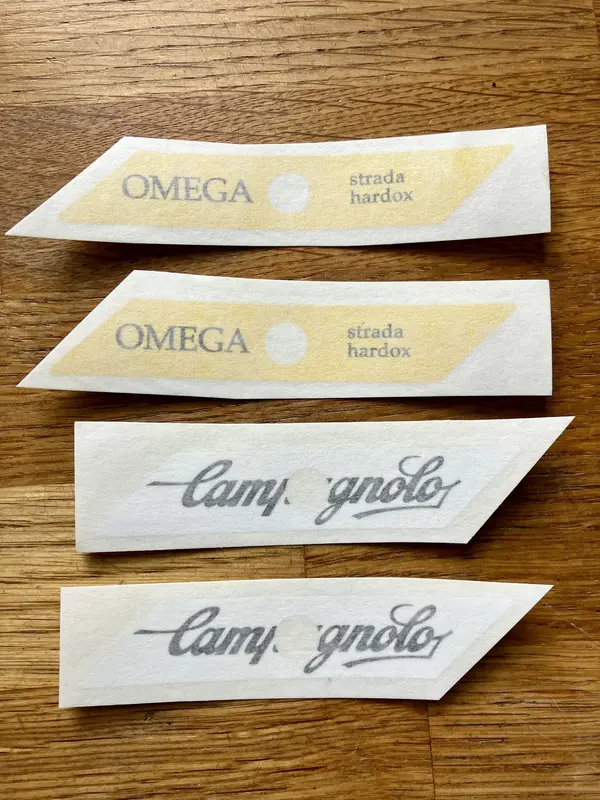

I also picked up some new rim decals for the other wheelset (the 32h ones) as the existing ones are just too scruffy. This 28’s are great though, and will clean up nicely.

The spokes arrived yesterday, and I found an hour this morning to lace up the front wheel. I’ve lost track of how many wheels I’ve built now, but I think this is the 9th pair, and exactly the same spec as what I used on my 1991 Merlin Titanium, which I incidentally tested downhill at just under 50mph last week. The thing was solid

I had planned on using either DT Revoltion or Sapim Laser spokes as they’re essentially the same as each other, and the best balance of weight and strength. As the Sapim are more widely available and significantly cheaper, it was an easy choice. They came in at 83p a spoke, and I’ll be using standard 12mm DT alloy nipples to help keep the weight down. I know what people say about alloy nipples, but providing you’re using quality nipples, and liberal amounts of copper grease when building them you’ll never see a problem. I’ve run them for years without issue. Plus, this bike isn’t going to see the rigours of our winter roads!

I also picked up some new rim decals for the other wheelset (the 32h ones) as the existing ones are just too scruffy. This 28’s are great though, and will clean up nicely.

The spokes arrived yesterday, and I found an hour this morning to lace up the front wheel. I’ve lost track of how many wheels I’ve built now, but I think this is the 9th pair, and exactly the same spec as what I used on my 1991 Merlin Titanium, which I incidentally tested downhill at just under 50mph last week. The thing was solid

Last edited: