You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yellow Hobbs winter beater of distinction (WBOD)

- Thread starter Jonny69

- Start date

Jonny69

Senior Retro Guru

Main headache/holdup at the moment is the shifters. I picked up some nice spoon-shaped Huret shifters which look appropriate for the frame, but they’re English threaded while the Campag shifter bosses are metric. I’m going to root through the pile of shifter bits to see if I’ve got anything I can substitute in:

However, if I can’t, I might have to re-think the front and rear mechanicals.

However, if I can’t, I might have to re-think the front and rear mechanicals.

Jonny69

Senior Retro Guru

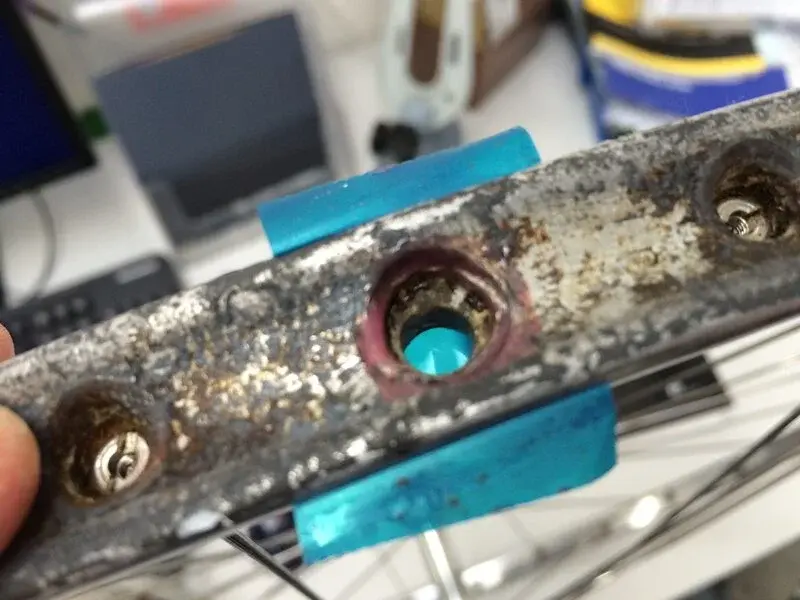

Securing that canti stud. I had a look at re-swaging it, but because it’s partially behind the fork blade I can’t get anything on it that I was confident enough I could give a decent hit without also hitting the fork. Next best is resorting to a bit of materials science.

Aaaaaages ago (2016) I needed to re-seat the valve hole eyelet on an early Fiamme sprint rim for my Parkes Lightweight. Again, it was an awkward job, a little bit corroded and I wasn’t confident I could get an appropriate hit on it without also mangling the rim. I decided to set it in place with some aerospace permanent structural epoxy and I’m happy that repair will outlive the rest of the rim:

The canti stud is swaged, so it can’t pull out but it does spin. One of the key features of this adhesive is it’s incredibly strong in shear. So a thin fillet around the back edge of the canti stud should be sufficient to stop it spinning even when I tighten the canti bolt.

I cleaned it back to bare metal using a combination of Stanley knife blade and small screwdriver, then degreased with isopropanol:

Then dabbed the tiniest amount of adhesive round the edge using a tiny spreader. Rotated the stud a couple of times to hopefully work a bit under the swage too:

The dab of red paint is on the side of the stud that had more yellow paint on it. I figured that was probably the side facing the open side of the bracket (which got hit with the most paint when it was sprayed) and when the stud is that way round it’s also the most parallel with the other stud.

Now it sits for 24 hours to cure.

Aaaaaages ago (2016) I needed to re-seat the valve hole eyelet on an early Fiamme sprint rim for my Parkes Lightweight. Again, it was an awkward job, a little bit corroded and I wasn’t confident I could get an appropriate hit on it without also mangling the rim. I decided to set it in place with some aerospace permanent structural epoxy and I’m happy that repair will outlive the rest of the rim:

The canti stud is swaged, so it can’t pull out but it does spin. One of the key features of this adhesive is it’s incredibly strong in shear. So a thin fillet around the back edge of the canti stud should be sufficient to stop it spinning even when I tighten the canti bolt.

I cleaned it back to bare metal using a combination of Stanley knife blade and small screwdriver, then degreased with isopropanol:

Then dabbed the tiniest amount of adhesive round the edge using a tiny spreader. Rotated the stud a couple of times to hopefully work a bit under the swage too:

The dab of red paint is on the side of the stud that had more yellow paint on it. I figured that was probably the side facing the open side of the bracket (which got hit with the most paint when it was sprayed) and when the stud is that way round it’s also the most parallel with the other stud.

Now it sits for 24 hours to cure.

Jonny69

Senior Retro Guru

Bottom bracket is in. I had to take it to my LBS to get them to chase the threads first, though, because it wasn’t threaded very far in and there was a bit of yellow paint sat in the threads. Combination of the two meant I couldn’t get my UN-55 very far in before it was way too tight.

Can I do a quick sanity check though? I could have sworn the left-hand threaded fixed cup went on the drive side and right-hand threaded cup with the lock ring went on the non-drive side. That’s right, isn’t it? On this frame it’s the other way round:

I thought at first the LBS had forced it in back to front, but I’ve taken it out to check and they have just chased the threads like I asked and fitted the bb. No evidence of cross-threading, mangling or thread re-cutting. Am I going mad?

Can I do a quick sanity check though? I could have sworn the left-hand threaded fixed cup went on the drive side and right-hand threaded cup with the lock ring went on the non-drive side. That’s right, isn’t it? On this frame it’s the other way round:

I thought at first the LBS had forced it in back to front, but I’ve taken it out to check and they have just chased the threads like I asked and fitted the bb. No evidence of cross-threading, mangling or thread re-cutting. Am I going mad?

Guinessisgoodforyou

rBotM Winner

You are correct, oh dearBottom bracket is in. I had to take it to my LBS to get them to chase the threads first, though, because it wasn’t threaded very far in and there was a bit of yellow paint sat in the threads. Combination of the two meant I couldn’t get my UN-55 very far in before it was way too tight.

Can I do a quick sanity check though? I could have sworn the left-hand threaded fixed cup went on the drive side and right-hand threaded cup with the lock ring went on the non-drive side. That’s right, isn’t it? On this frame it’s the other way round:

View attachment 919956

I thought at first the LBS had forced it in back to front, but I’ve taken it out to check and they have just chased the threads like I asked and fitted the bb. No evidence of cross-threading, mangling or thread re-cutting. Am I going mad?

PhillB

GT Fan

I'm not sure what the implications would be, but it reminds me of the Italian BB I have on my 80's Guerciotti which is not reverse threaded. It slowly undid as I rode it. I put some thread lock on the BB thread and haven't had a problem since... probably some folks who know more than me could give some advice.Bottom bracket is in. I had to take it to my LBS to get them to chase the threads first, though, because it wasn’t threaded very far in and there was a bit of yellow paint sat in the threads. Combination of the two meant I couldn’t get my UN-55 very far in before it was way too tight.

Can I do a quick sanity check though? I could have sworn the left-hand threaded fixed cup went on the drive side and right-hand threaded cup with the lock ring went on the non-drive side. That’s right, isn’t it? On this frame it’s the other way round:

View attachment 919956

I thought at first the LBS had forced it in back to front, but I’ve taken it out to check and they have just chased the threads like I asked and fitted the bb. No evidence of cross-threading, mangling or thread re-cutting. Am I going mad?

Guinessisgoodforyou

rBotM Winner

That's the issue.I'm not sure what the implications would be, but it reminds me of the Italian BB I have on my 80's Guerciotti which is not reverse threaded. It slowly undid as I rode it. I put some thread lock on the BB thread and haven't had a problem since... probably some folks who know more than me could give some advice.

Jonny69

Senior Retro Guru

Ok, well at least I know I was right, then. The threads 100% do not show any sign of being re-threaded in the opposite direction, are clean and the bb has not been forced in. I even checked last night that I wasn’t trying to get the cup started on the wrong side but it’s usually obvious because it won’t catch. Was I working back-to-front? Wtf.

Well, I’m not overly concerned. My USSR track bike which is my daily is right-hand threaded on both sides and that hasn’t been a problem through two bb’s and 30,000+ miles. And I really stand on that thing, it doesn’t get a easy life. What’s just really confusing is I swear last night I had the shouldered left-threaded body of the UN-55 on the drive side and the alloy right-threaded cup on the non-drive side. Something would have got mangled in the process.

Well, I’m not overly concerned. My USSR track bike which is my daily is right-hand threaded on both sides and that hasn’t been a problem through two bb’s and 30,000+ miles. And I really stand on that thing, it doesn’t get a easy life. What’s just really confusing is I swear last night I had the shouldered left-threaded body of the UN-55 on the drive side and the alloy right-threaded cup on the non-drive side. Something would have got mangled in the process.

fiveSixteenths

Senior Retro Guru

Yikes!Main headache/holdup at the moment is the shifters. I picked up some nice spoon-shaped Huret shifters which look appropriate for the frame, but they’re English threaded while the Campag shifter bosses are metric. I’m going to root through the pile of shifter bits to see if I’ve got anything I can substitute in:

View attachment 917696

However, if I can’t, I might have to re-think the front and rear mechanicals.

Similar threads

- Replies

- 13

- Views

- 398