You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Norwegian GT LOBO STS "

- Thread starter Lowman

- Start date

Magpiegifts

Kona Fan

- Feedback

- View

That is looking fantastic!

Your hard work and attention to detail is paying off definitely

Your hard work and attention to detail is paying off definitely

Thank you so much for kind wordsThis is ace. Great work!

Lovely bikes, but Jesus Christ, don't store your guitar like that!

From all the way back when I bought and built this bike in 1998,i initially wanted to spec it out with some certain favourite components.One of these components was the Azonic Shorty stem,which i always loved the look of,especially the black one. History tells ,that I never got one,cause I settled for alot of the parts from the donor bike,the old Sts Dh bike.

So 3 weeks ago,, I was looking around on ebay,and behold,An Azonic Shorty Stem,the 45mm version ,in black

I bought it, knowing it had a repair done to it,the threads on the headtube clamp fitting was gone,but the overall condition was soo good,i had to have it

So ,,I have now got it home, and I'm super stoked finally getting one

So now,I wanted to show you how i fixed it

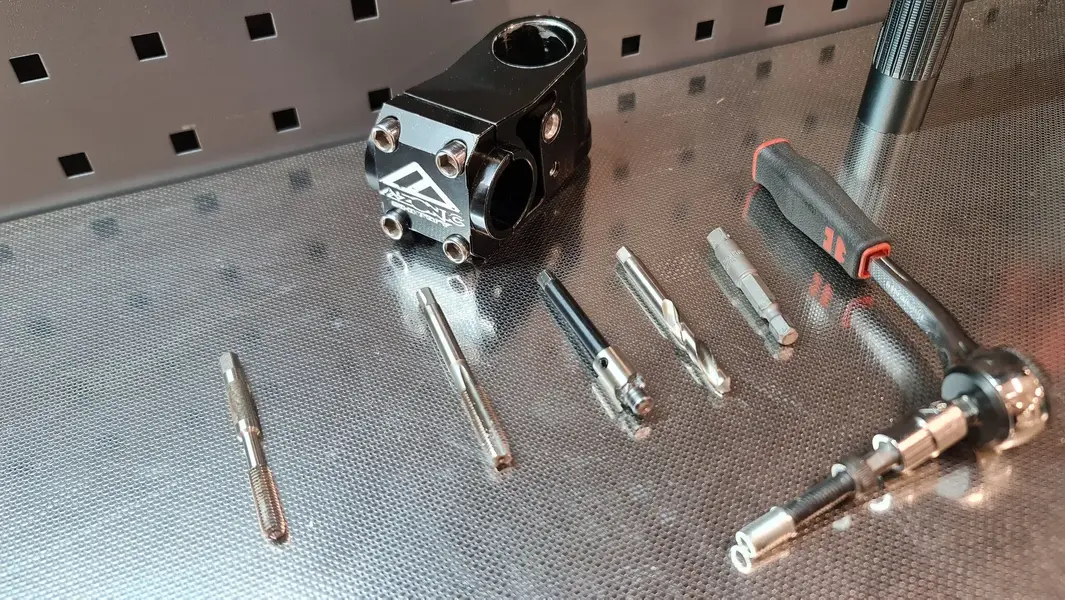

I used Wurth Time Sert Thread inserts. These are far superior to the well known "helicoil " threads,which basically sux.The Time Sert ones ,are massive Steel inserts,and not just loose threads like the Helicoil.

Also the best part is that using these threads,you are maintaining the original bolt size.

Eitherway, here is step by step pictures of the jobb, and I hope you like it.

I still have left to sort out two new black bolts,but they are on order.

So here is the job in chronological order

Got the new stem home. "bad " repair of the broken threads,by just putting on a longer bolt ,with a nut on the other end.Works fine,but i want it to be proper.

Decided to do only the hole with the broken threads first....but----

But then.-.My ocd kicked in,and i decided to do the other one too So now both of them are up for the job,holding everything in placen,tight and snug

So now both of them are up for the job,holding everything in placen,tight and snug

Step 1: Drill a new hole,with the special diameter drill bit

Step 2:Countersunk the hole,

Countersunk done, Bitofa shame with the damage in the anodizing around the previous " repaired hole"...The nut made some scoring marks there..but i used a black marker pen, to soften the sight of the damaged anodizing.

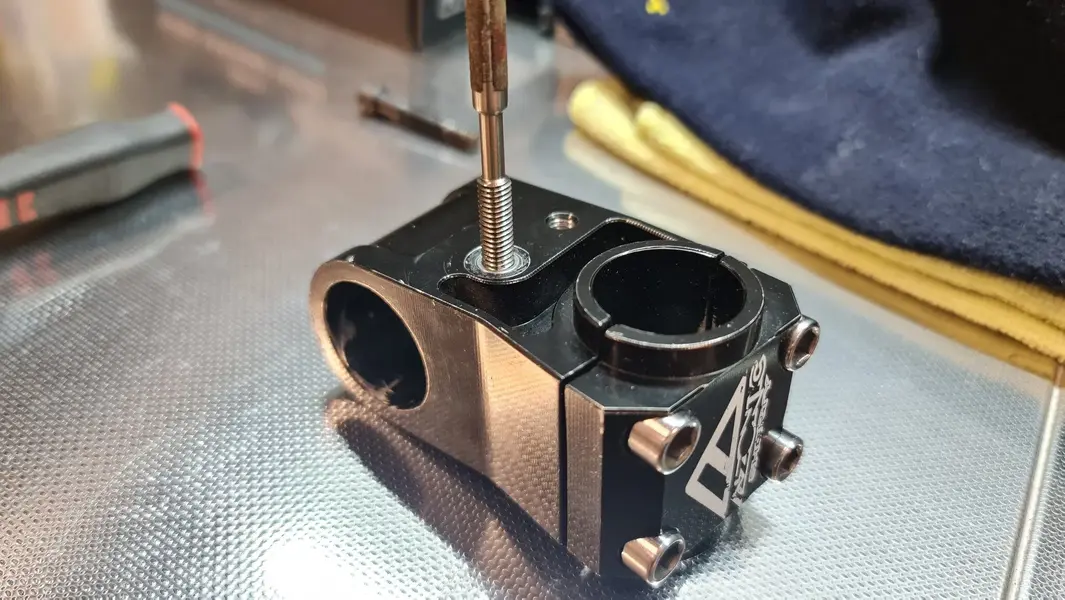

Step 3:Then rethreading the hole,with a special size thread bit,specific to the Wurth TimeSert kit,to accept then the thread insert

Threads done

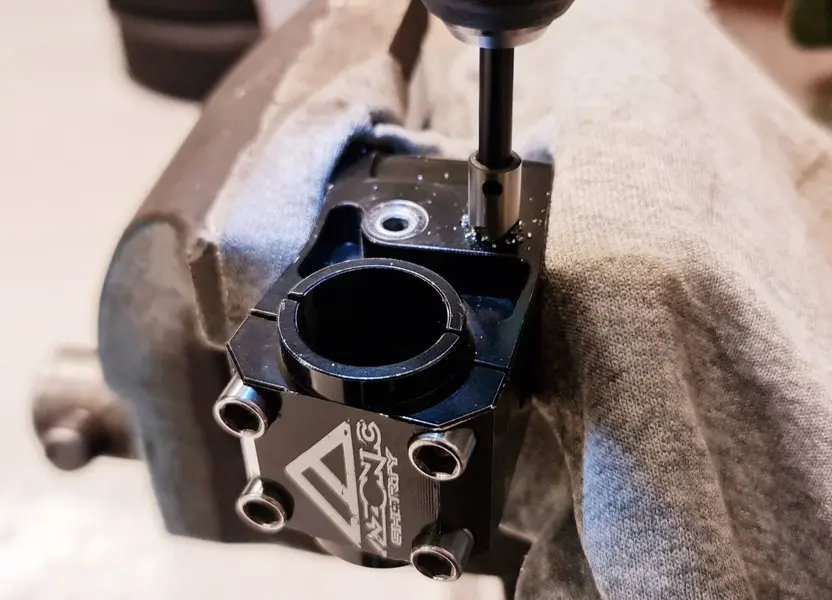

Step 4: inserting the Wurth TimeSert thread insert. No need for threadlock,.as the tool seeen on the picture,holds the insert in place..and as it goes in..it expands the insert..so it sticks in there

Step 5: Enjoy the new steel insert threads Also,as you can see..the scoring marks on the top hole,is less visible now due to the fact that i touched it up with my black marker pen.Works perfectly fine

Also,as you can see..the scoring marks on the top hole,is less visible now due to the fact that i touched it up with my black marker pen.Works perfectly fine

So 3 weeks ago,, I was looking around on ebay,and behold,An Azonic Shorty Stem,the 45mm version ,in black

I bought it, knowing it had a repair done to it,the threads on the headtube clamp fitting was gone,but the overall condition was soo good,i had to have it

So ,,I have now got it home, and I'm super stoked finally getting one

So now,I wanted to show you how i fixed it

I used Wurth Time Sert Thread inserts. These are far superior to the well known "helicoil " threads,which basically sux.The Time Sert ones ,are massive Steel inserts,and not just loose threads like the Helicoil.

Also the best part is that using these threads,you are maintaining the original bolt size.

Eitherway, here is step by step pictures of the jobb, and I hope you like it.

I still have left to sort out two new black bolts,but they are on order.

So here is the job in chronological order

Got the new stem home. "bad " repair of the broken threads,by just putting on a longer bolt ,with a nut on the other end.Works fine,but i want it to be proper.

Decided to do only the hole with the broken threads first....but----

But then.-.My ocd kicked in,and i decided to do the other one too

Step 1: Drill a new hole,with the special diameter drill bit

Step 2:Countersunk the hole,

Countersunk done, Bitofa shame with the damage in the anodizing around the previous " repaired hole"...The nut made some scoring marks there..but i used a black marker pen, to soften the sight of the damaged anodizing.

Step 3:Then rethreading the hole,with a special size thread bit,specific to the Wurth TimeSert kit,to accept then the thread insert

Threads done

Step 4: inserting the Wurth TimeSert thread insert. No need for threadlock,.as the tool seeen on the picture,holds the insert in place..and as it goes in..it expands the insert..so it sticks in there

Step 5: Enjoy the new steel insert threads

Last edited:

Similar threads

- Replies

- 6

- Views

- 636

Latest posts

-

'93-4 (?) Marin Team Issue non-cat spec (sorry, purists) 👀

- Latest: Carlwilliams1984

-