That must feel good starting to get parts ready to hang off the frame.

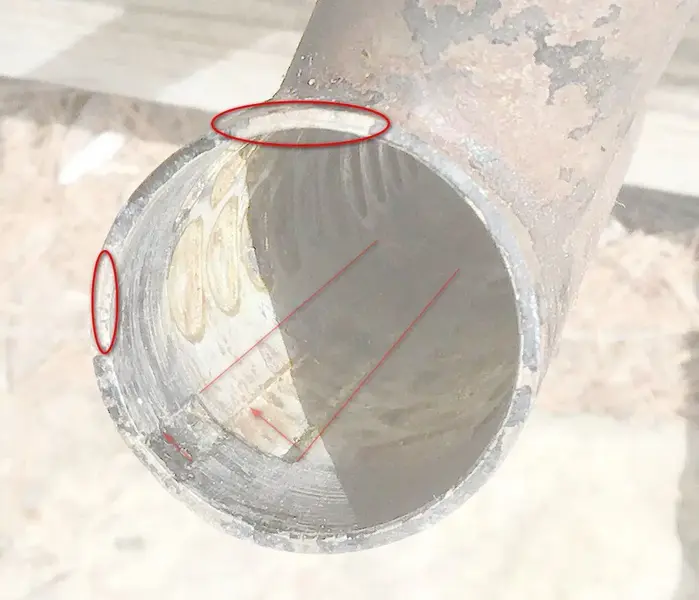

Throwing this out to you metal work folks. I'm going back to dimples, pimples or holes, so sorry to side track a bit. The photo on page 1 is down the head-tube if I'm not mistaken? Anyhow, I did some photo tweaking. This is what I think.

The head-tube starts out in life thin gauge. Probably the Sifret stuff or something seamless.

An additional "universal shim sort of thing" is made with drilled out holes in sheet metal. It's rolled to a round shape, and inserted in the head-tube. Springyness and friction keep it all in place ready for brazing. Gaps between the headtube and lattice shim are filled through capillary action.

I've marked bits in red which I think are clues. This way, I guess you get all the advantages of light and strong. You would also get a perfectly smooth outer surface, which I can't see how it could be done with pressing. I can't see how you could get a drill / milling machine in such a small diameter, but you could get a blow torch in. The end result is impressive, and could be used to beef-up other areas while keeping the weight down. I don't know if double butted tube were invented back then.

Throwing this out to you metal work folks. I'm going back to dimples, pimples or holes, so sorry to side track a bit. The photo on page 1 is down the head-tube if I'm not mistaken? Anyhow, I did some photo tweaking. This is what I think.

The head-tube starts out in life thin gauge. Probably the Sifret stuff or something seamless.

An additional "universal shim sort of thing" is made with drilled out holes in sheet metal. It's rolled to a round shape, and inserted in the head-tube. Springyness and friction keep it all in place ready for brazing. Gaps between the headtube and lattice shim are filled through capillary action.

I've marked bits in red which I think are clues. This way, I guess you get all the advantages of light and strong. You would also get a perfectly smooth outer surface, which I can't see how it could be done with pressing. I can't see how you could get a drill / milling machine in such a small diameter, but you could get a blow torch in. The end result is impressive, and could be used to beef-up other areas while keeping the weight down. I don't know if double butted tube were invented back then.