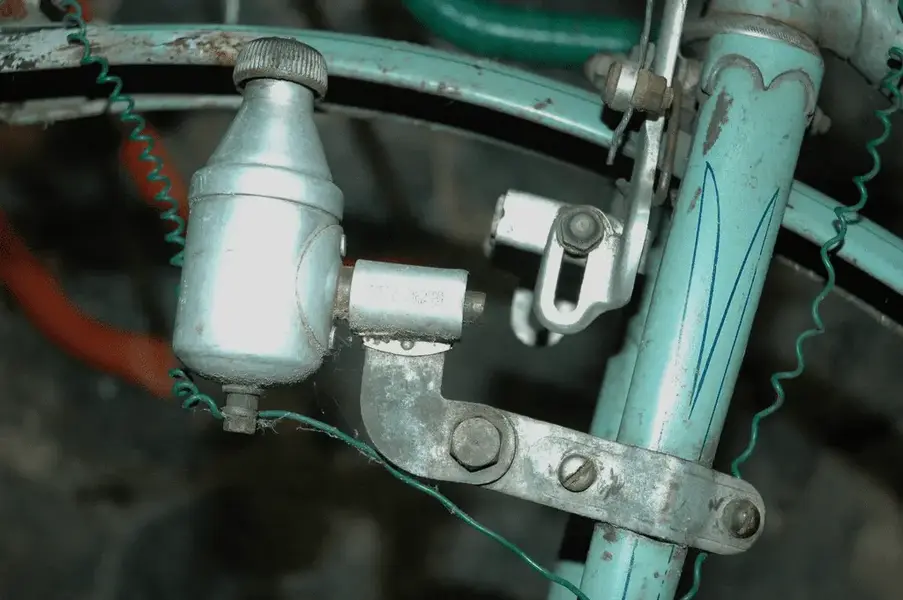

Dynamo Off

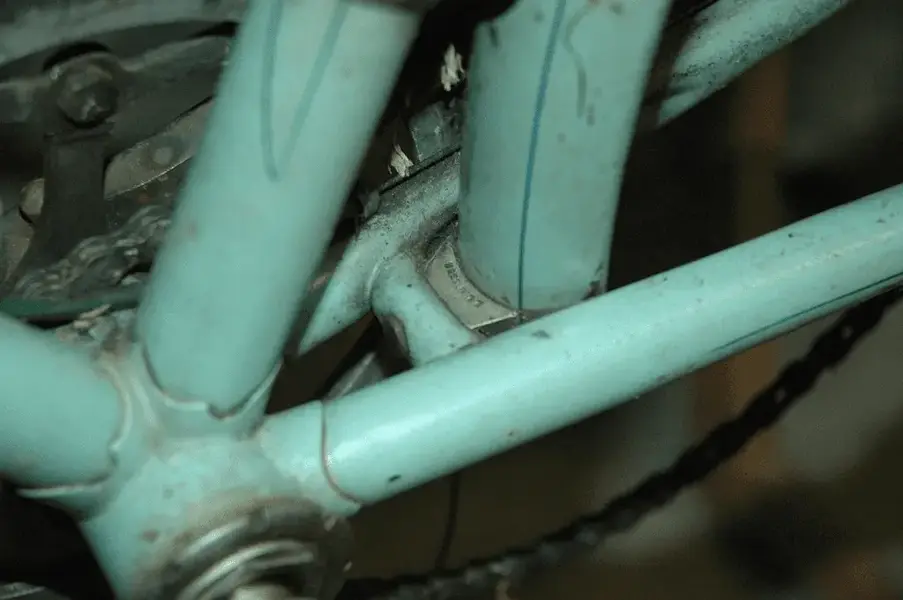

Fairly straight forward. For those who don't know, the dynamo also serves as a junction box to connect the front and rear light. You unwire starting from the dynamo, back to the mudguards. The wire is typically soldered to the light terminals. My heart already started to sink - different screws with different nut sizes and I only just started. Good news, it was off, cables left intact to the mudguards, and importantly no fork crimp damage or big rust hole Some evidence that the dynamo got repositioned a few times - presumably for different tyres.

Some evidence that the dynamo got repositioned a few times - presumably for different tyres.

Fairly straight forward. For those who don't know, the dynamo also serves as a junction box to connect the front and rear light. You unwire starting from the dynamo, back to the mudguards. The wire is typically soldered to the light terminals. My heart already started to sink - different screws with different nut sizes and I only just started. Good news, it was off, cables left intact to the mudguards, and importantly no fork crimp damage or big rust hole