rmwesley

Retro Guru

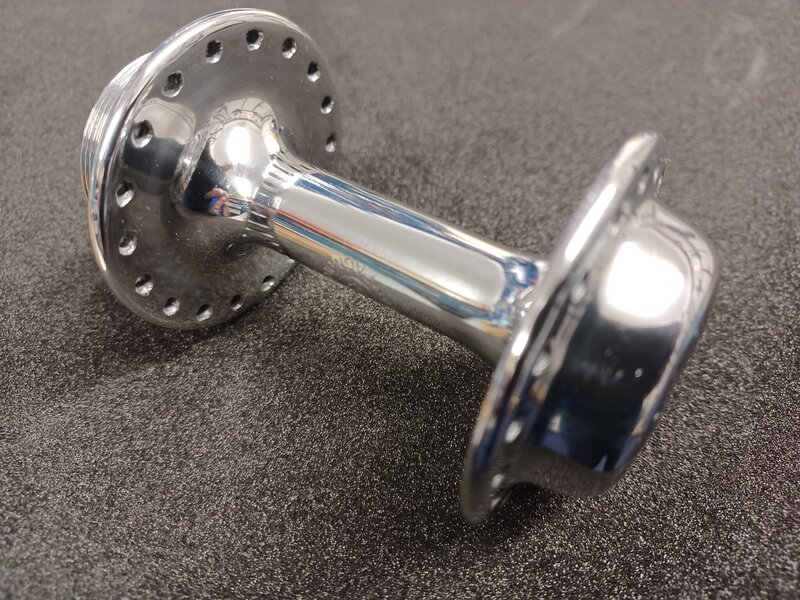

I'm going to reuse the spokes to rebuild the wheels since they look in pretty good shape. However, I'm definitely no spoke-whisperer who can determine tension by flicking the spokes like a piano tuner. Therefore, step one is to calibrate my tensiometers for these specific spokes.

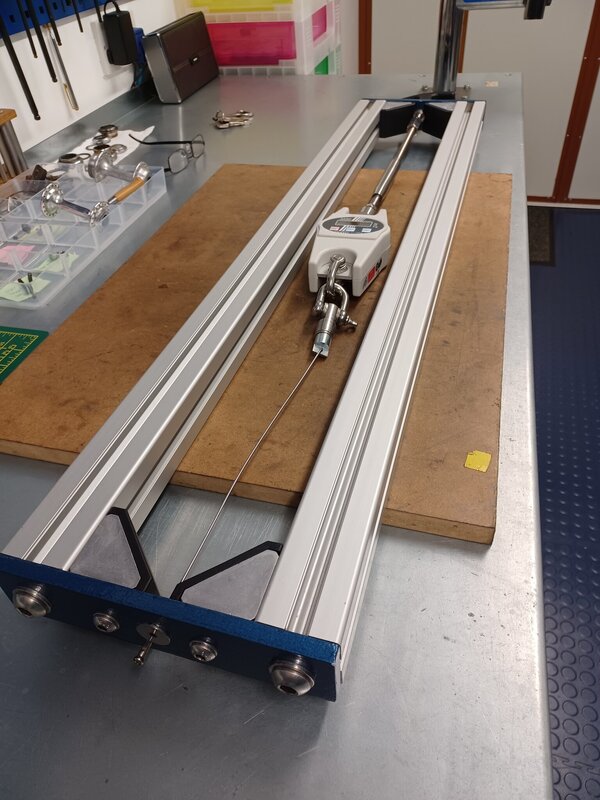

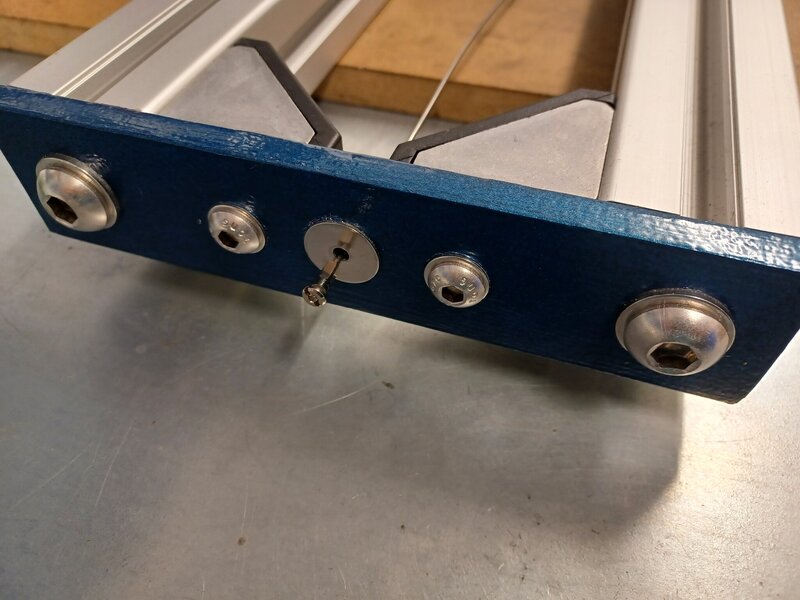

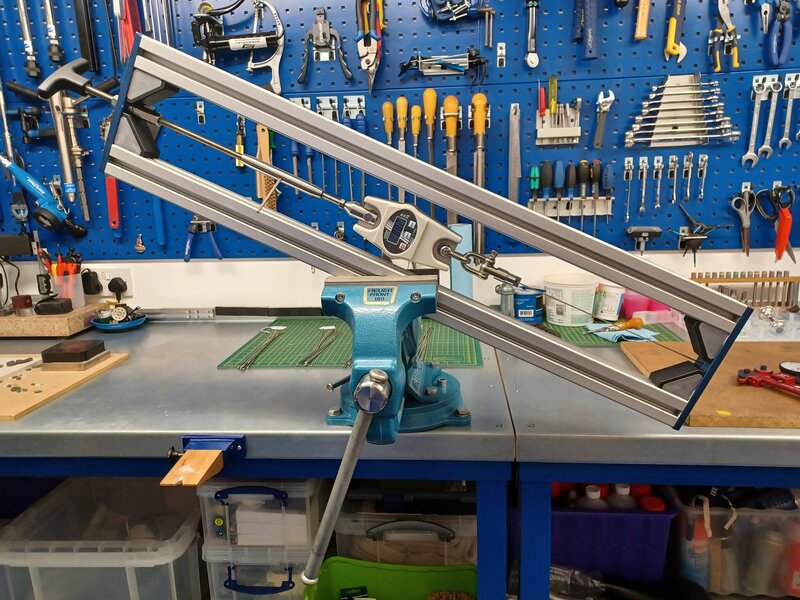

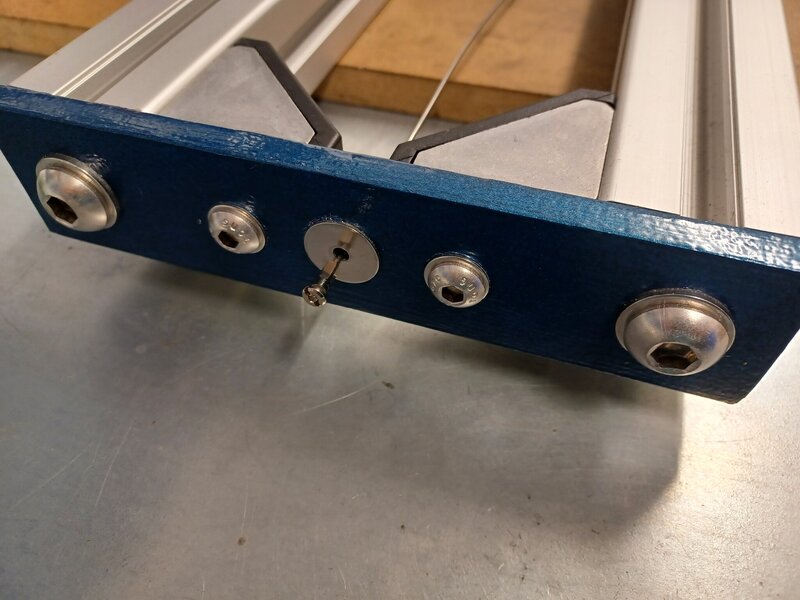

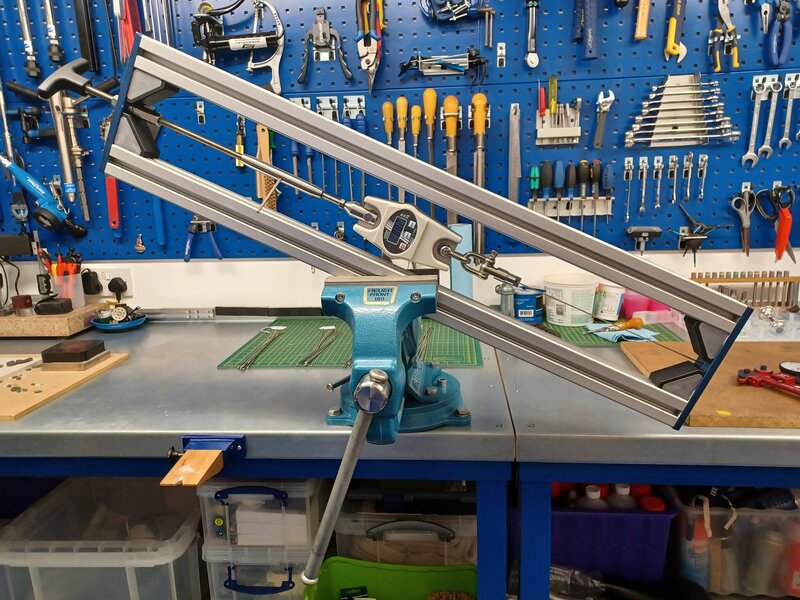

I knocked up this tension gauge a while back using a crane scale.

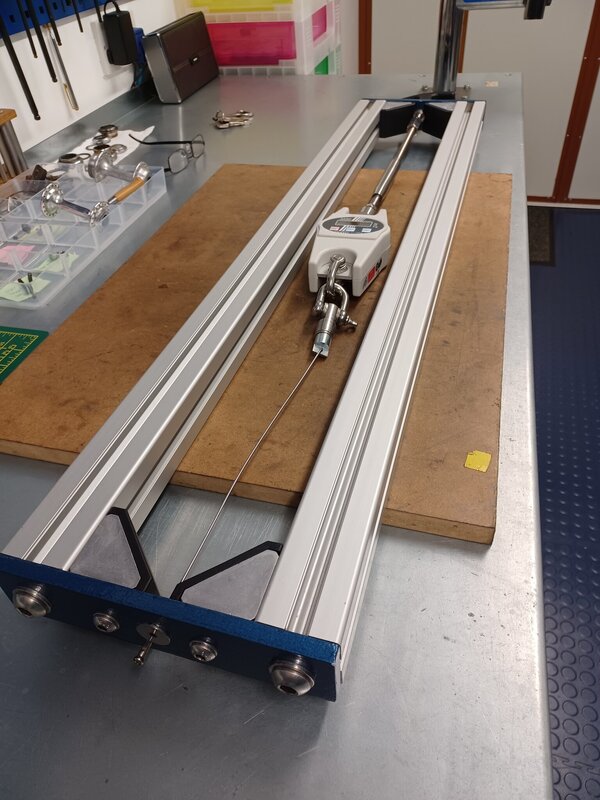

Just need to thread in one of the old spokes.

And try to replicate the angle of the spoke when it will be sitting in the wheel jig.

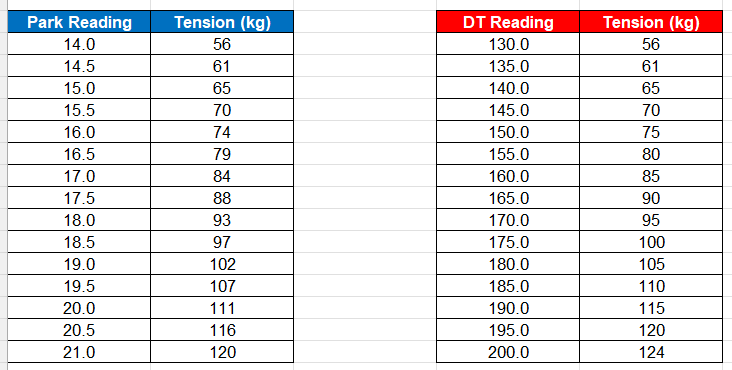

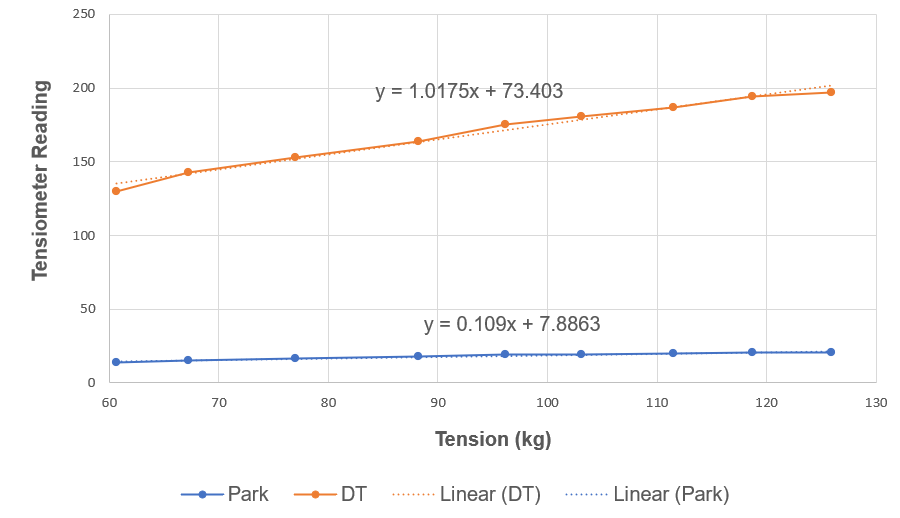

Then crank up the tension in approx. 10kg increments taking readings as you go.

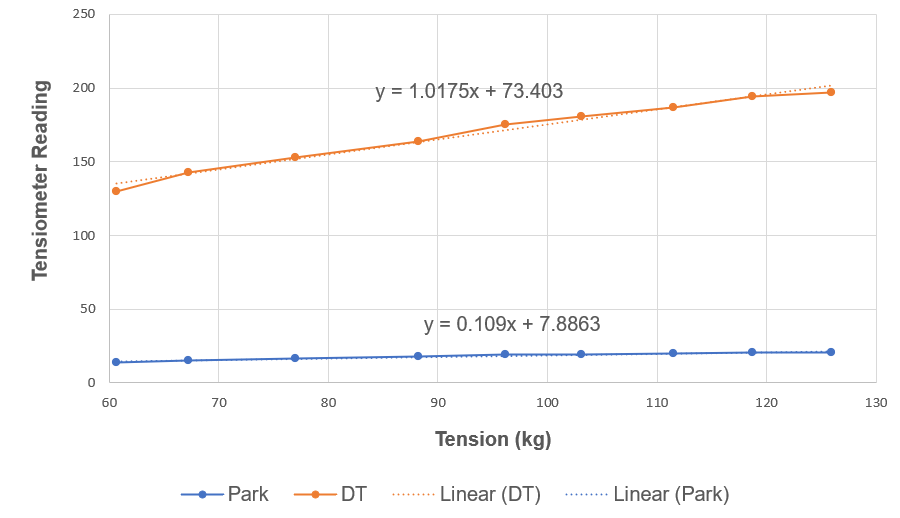

Once done, you can then plug the numbers into Excel and approximate the readings to a linear graph.

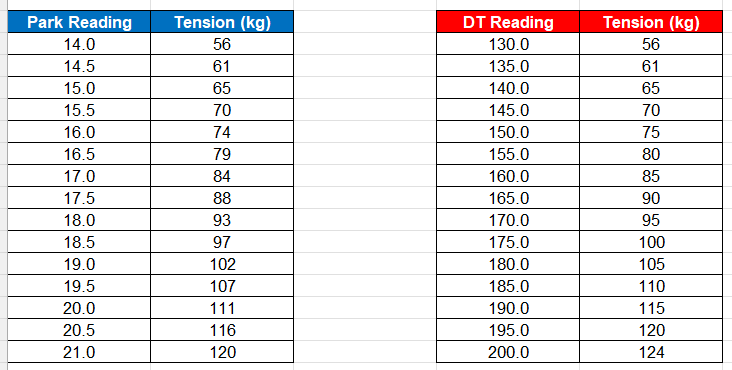

The linear approximation can then be used to calculate a bespoke tension chart.

I knocked up this tension gauge a while back using a crane scale.

Just need to thread in one of the old spokes.

And try to replicate the angle of the spoke when it will be sitting in the wheel jig.

Then crank up the tension in approx. 10kg increments taking readings as you go.

Once done, you can then plug the numbers into Excel and approximate the readings to a linear graph.

The linear approximation can then be used to calculate a bespoke tension chart.