I think the lightest in that period is the ti axled Specialized spd pedal. About 300gr/pair, i think. Everything else was around 350 with steel axles. There must be ti axled variants, out there. I thought the Stealth was mid 90's but seems to only just creep in, at the last.

Edit: there was a titanium axle available for the Shimano m737. That is early-mid 90's pedal. Maybe the first spd?

Thanks for the recommendations. I'll look into those, though am leaning more toward a platform pedal. Seems like everyone and their mother replicated the Odyssey Svelte Racing pedal by about 1994/1995 per browsing old magazines. There is a manufacturer called Shogun which goes all the way back to the early 90's (maybe earlier?) which made a carbon/titanium platform pedal with a weight of 108 to 130 grams per pedal. Maybe something like that, if I can find them?

The Road version of the Titanium Grafton pedals, the Speedlite, is smaller in size and very light; just 262 grams for the pair according to BikePro.

Star12

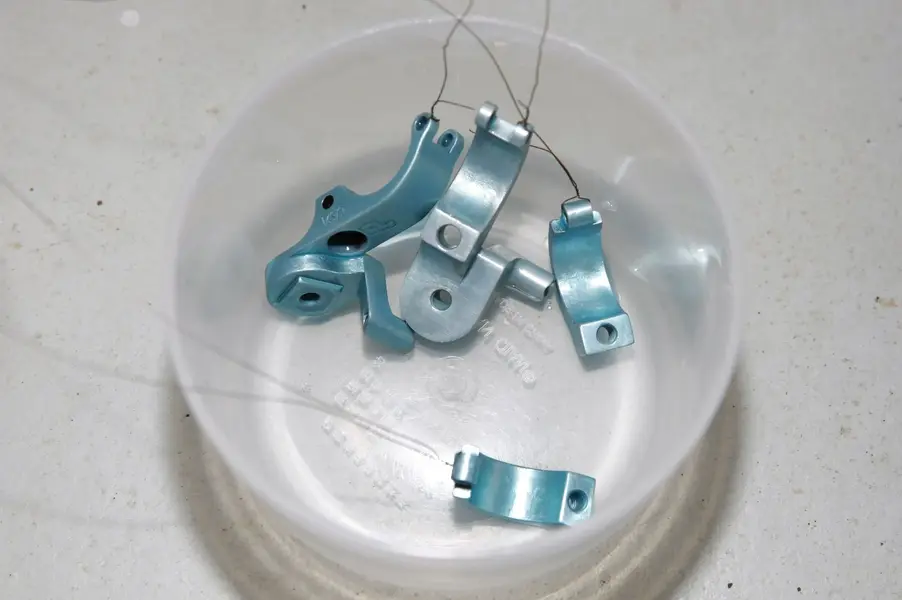

Sounds hot...but also very expensive. There's a set on eBay for 450 euros, then that crazy guy in the US selling the turquoise ones for $1000.

Paragon Machine Works actually

Thanks man. You are a walking encyclopedia.

The lightest pedals I know with a retro look are the Steinbach pdals @ 190g/pair. Not sure though if they are still being made or where to get them otherwise.

Oh

. There is a post on mtn-news with a photo of the pedals being weighed at 181 grams. Now...I need to find a set. Any leads?

A bit late but just read through the thread, some interesting posts.

Liking some of the colours, though personally I would have stuck with the plain Ti on the stem for this build. Agree about the lightness though, I have one also and with the matching bar, very light set up.

Looking forward to seeing more pictures of the frame coming together.

View attachment 745652

Sorry I wasted an hour of your time with all the reading.

. I promise I am not ADD or schizophrenic. Once the bike is complete I will be editing the first few posts with updated comments as the build went full 180 by about the second page.

The naked titanium is quite nice and looks good. Full weight of the stem and bars together? Make sure to swap out those bolts for aluminum or titanium and shave off 12 grams or so. The stems are totally underrated. Lighter than Litespeed of the same era (or very close) IIRC.

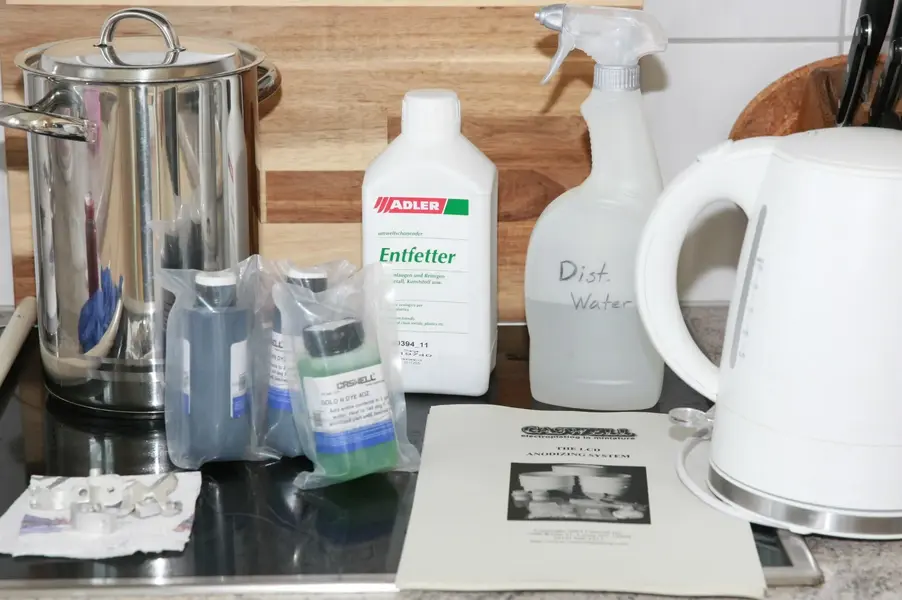

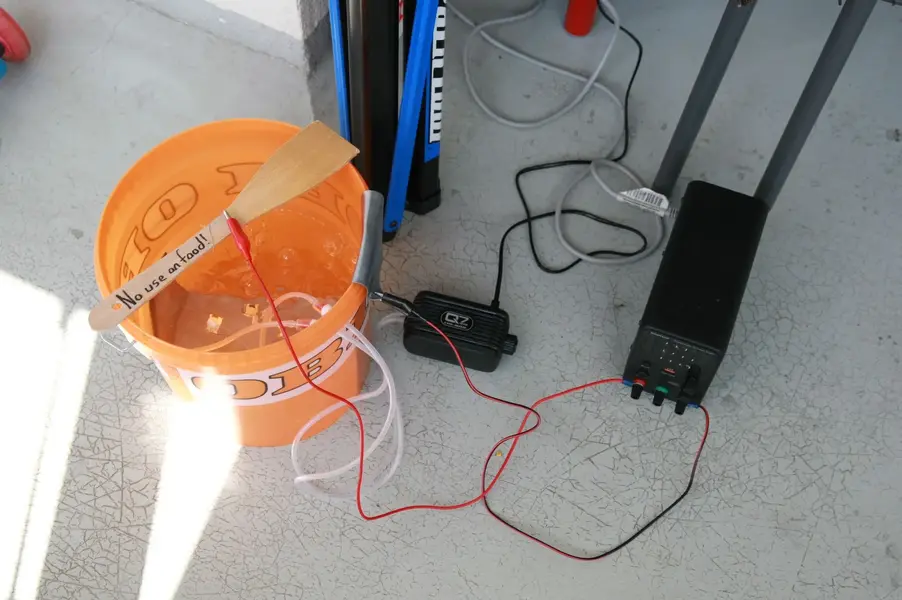

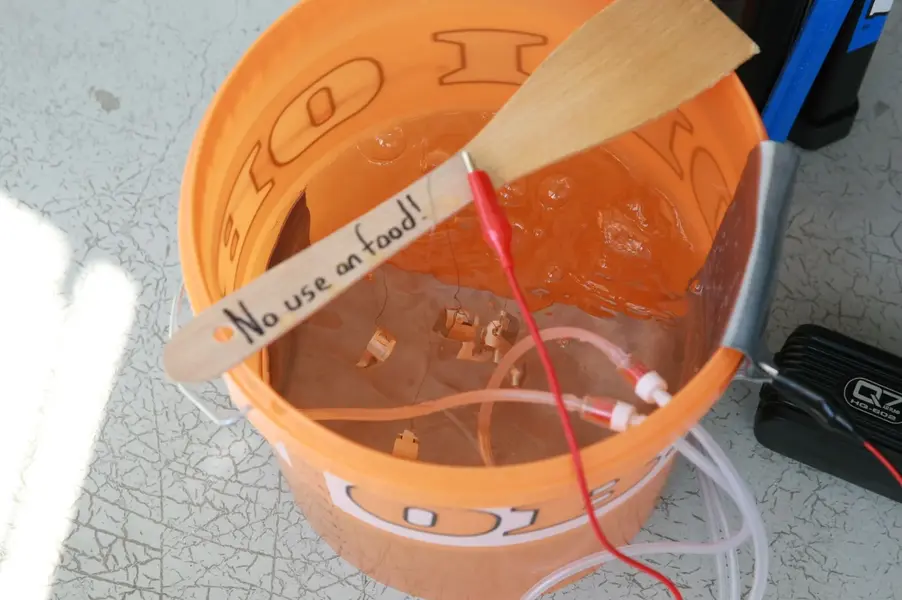

For this Serotta build, I am going full retard on the color scheme, so the sky is the limit at this point. Plus this is my motivation to learn how to anodize whether I botch it or not. Once I find the rims, I'll start building. In the mean time, I need to decide on cranks/rings then anodize accordingly. Overall, I have quite a bit of anodizing to do.

Also this Tune guy here in Germany, Christian..., I really hope he has another batch of Ti steerer tubes coming up soon. This is also stalling the build and I want to buy six or so to have on hand.