Here is the back story explaining the decisions taken when ordering and building the Roberts Dogsbolox in 1994.

I had owned a few mountain bikes before this one. An Overburys Pioneer (that got stolen), a Roberts Rough Stuff and a Roberts White Spider. I also spent most Sundays from 1987 to 1992 working at Smithbrook Kilns Mountain Bike shop near Cranleigh in Surrey, owned by my friend Graham Koster. I spent most of my time in the workshop building new bikes or repairing them. My experience there helped me formulate the ultimate bike I wanted to own.

So many bikes would come in needing replacement wheels, bottom brackets and headsets because the bearings were trashed or had seized cables due to owners lack of maintenance or jetwashing the bikes and flushing out the grease. I decided to build a bike with cartridge bearings so they could be replaced without buying complete new units such as wheel hubs or headsets. So the wheels, bottom bracket and headset all have sealed cartridge bearings. I installed Middleburn cable oilers to keep braking and gearchanging nice and smooth.

The late 1980s was a time of innovation and new small startup companies selling upgraded high quality parts. Working at the cycle shop brought me into contact with local enthusiasts and companies offering exotic parts. Venhill was a local company making automotive brake lines and they branched out to include cycle components including the titanium chainring bolt set used on my bike. I guy I met (sadly I forget his name) started a company call Zero components from his house Cranleigh and he designed and commissioned an engineering company to make the titanium quick release skewers. He would come into the shop often to talk to Graham and show his new designs. I remember visiting him at home one night to buy a set of the skewers.

The other main build criteria was lightness. Everything was designed to lose weight; from the original frame build request for minimal fillets on the tube joints and a lightweight handlebar stem to sourcing the lightest version of every component on the bike. So Specialised Umma Gumma kevlar beaded tyres were purchased, Vittoria latex inner tubes (the originals lasted 26 years and a new set has now replaced them), the obligatory Selle Italia titanium flite saddle was added onto the Ringle Moby seat post. I had seen so many seat posts chewed with deep gouges from rough internal seat tubing that I was determined to keep mine looking pristine. Through careful measuring and setting the seat too high I worked down to the correct height. No scratches are visible on my seat post!

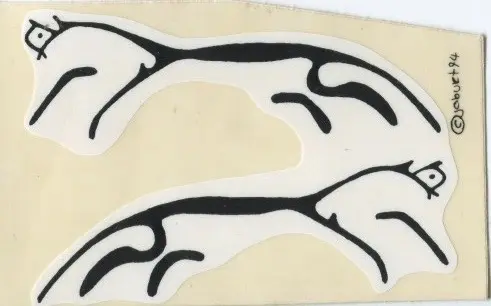

Finally I wanted a Pearl white frame. No other colour would do. My colour choice was influenced by the Renault 5 turbo I saw in the mid 1970’s with was a metallic pearl white with a hint of yellow. In keeping with the colour scheme everything had to compliment the frame so grey tyres had to be used, silver seat stem and handlebar, bar ends and clear Tomac Grips, the Ringle Mo Jo cable hangers and all the nuts and bolts had to be silver.

Maybe I got a bit obsessed with this build but I think it has stood the test of time and it looks as good now as it did back then in 1994 and can hold its head up high standing next to any of the amazing modern bikes on the market today. Out on the trails though it may be a different matter!

Everything about this bike (literally from the ground up, the frame, the components) was due to my choices and how I dreamed the perfect bike should be. I have owned this bike nearly 29 years, been with me through many house moves, two marriages, my constant companion , my happy thought when times were bad, it let explore the trails and the wonderful countryside around me , it let me forget the stresses of everyday life, it is part of me, part of my DNA and my biking history (in a way that a mass produced bike could never be) and nothing since has ever come close in my eyes to maybe tempt me away from this wonderful, my truly forever bike.