Well, brazing is fairly easy to kit out, and a lot more tolerant of inexperience than welding. Mistakes can be undone, or rectified, or hidden, or tidied up a lot easier than welded ones.

No need for a framebuilding course, but there might be something available at local Technical College or High School, but metalworking courses are getting pretty rare, and within that brazing itself is pretty niche these days. There are some specific brazing courses around, such as this at Weldspace in Plymouth. Where are you based?

Many have relied on YouTube (Fillet and capilliary, but not HVAC, copper or aluminium brazing), and lots of practice to get confident enough.

Apart from basic workshop tools (Vice, emery cloth, hacksaw and files etc) the main thing you need a decent heat source. The standard option is oxy-acetylene welding torch, but brazing is also possible with the more friendly oxy-propane or oxy-propylene/pro-fuel set up. It's slightly lower temp and needs special regulators and nozzles on the torch, but is safer than Oxy-Acetylene, and does not usually screw up your house insurance.

OA kits can be hired (https://www.nationaltoolhireshops.co.uk/product/oxy-acetylene-kit-hire/) less bottles, but another £30 above the weekly rate would buy a kit to own, the Acetylene regulator and the nozzle would need to be changed out if you went with Profuel or propane.

Gas of all sorts can be sourced rent-free from HobbyWeld or SGS, who both have distributors all over. Cost for the 2 bottles would be around £150 + £200 bottle deposit.

A suitable seat tube can be bought from specialist suppliers (Ceeway) for £10-30 depending on spec and steel alloy, along with bronze filler and flux to match. Ceeway also sell practice kits of plain tubes and lugs. Peter at Ceeway also sells some sleeving tube 28.6mm internal diameter, which could be formed into an external sleeve for the existing seat tube.

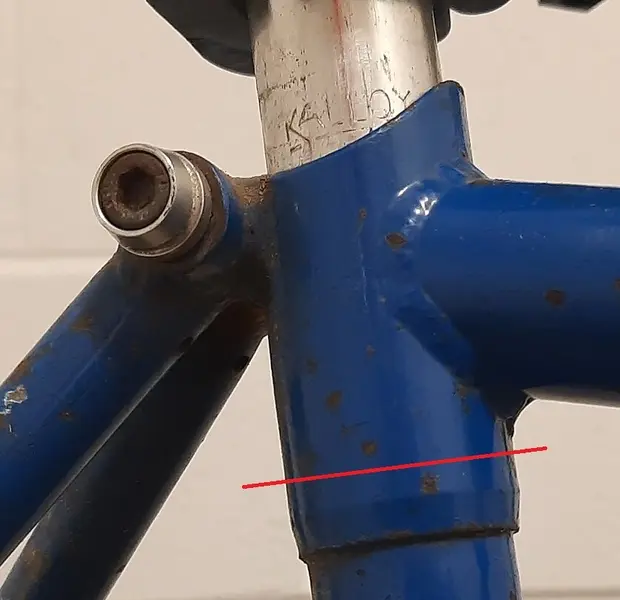

Do you have a good pic of the seat lug area?

All the best,

No need for a framebuilding course, but there might be something available at local Technical College or High School, but metalworking courses are getting pretty rare, and within that brazing itself is pretty niche these days. There are some specific brazing courses around, such as this at Weldspace in Plymouth. Where are you based?

Many have relied on YouTube (Fillet and capilliary, but not HVAC, copper or aluminium brazing), and lots of practice to get confident enough.

Apart from basic workshop tools (Vice, emery cloth, hacksaw and files etc) the main thing you need a decent heat source. The standard option is oxy-acetylene welding torch, but brazing is also possible with the more friendly oxy-propane or oxy-propylene/pro-fuel set up. It's slightly lower temp and needs special regulators and nozzles on the torch, but is safer than Oxy-Acetylene, and does not usually screw up your house insurance.

OA kits can be hired (https://www.nationaltoolhireshops.co.uk/product/oxy-acetylene-kit-hire/) less bottles, but another £30 above the weekly rate would buy a kit to own, the Acetylene regulator and the nozzle would need to be changed out if you went with Profuel or propane.

Gas of all sorts can be sourced rent-free from HobbyWeld or SGS, who both have distributors all over. Cost for the 2 bottles would be around £150 + £200 bottle deposit.

A suitable seat tube can be bought from specialist suppliers (Ceeway) for £10-30 depending on spec and steel alloy, along with bronze filler and flux to match. Ceeway also sell practice kits of plain tubes and lugs. Peter at Ceeway also sells some sleeving tube 28.6mm internal diameter, which could be formed into an external sleeve for the existing seat tube.

Do you have a good pic of the seat lug area?

All the best,

Last edited: