Who is Paul Brodie, and what does he do in his shop? This is a good question. On Velocipede Salon I read recently that I'm a "framebuilder who made some pretty good frames in the 80's and early 90's." Not much has been heard from me (bicycle wise..) for about a decade, so maybe I'm a "has-been", a washout...

Here's the truth: back in those days I had a dozen employees at the high point, and I was frantically running around trying to manage (in no particular order..) employees, payroll, lawsuits, lawyers, magazines, ads, distributors, WCB, PST, GST, fire code regulations, landlords, shop leases, accountants, book-keepers, new products, trade shows, race team, frame production, R&D, brochures, Test of Metal race, warranties, marketing, customers, sales reps, tubing orders, and more. I wore too many hats, and don't think I did any of the above particularly well. I spent little time on the shop floor actually "making things"...

This last decade has been spent (mostly alone..) in my shop making LOTS out of metal. I have made from scratch, four 1919 Excelsior Boardtrack racers, engines and all. I have learned many things about metals and fabrication. My skills have improved as I discovered new techniques and tried new things.

So, what's going on in my shop right now? This is the bike I'm building from scratch. An 1888 Whippet full suspension bike... the drawing comes from Bicycles and Tricycles, a great book by Archibald Sharp, first published in 1896 >

right now I'm working off this photo of the frame linkage; this 1888 Whippet is in a museum 3000 miles away and lives in the basement under a sheet of plastic>

I machine a short tube in the lathe, and then file a curved outer surface so it looks like a casting..

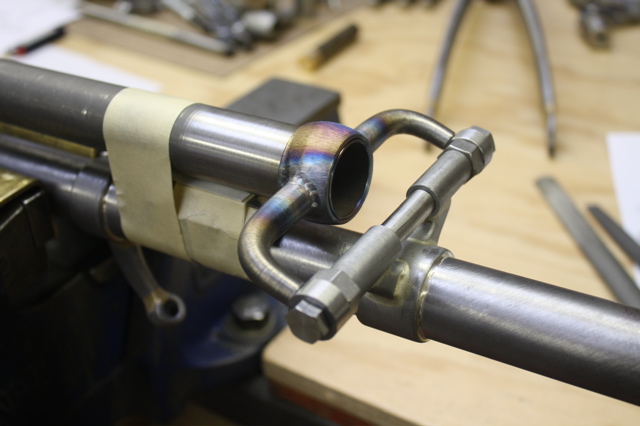

Here I've setup a little bending fixture in my vise. The rod is 4140 machined at a 2 degree taper, heated red hot, and bent to a right angle >

because I tapered it Big to Small, the end of the now bent and tapered rod is still perfectly faced, and sits perfectly on the tube's spotfaces for TIG welding..

after TIG welding, it reminds me of cattle for some reason...

here it sits over the frame tube, positioned for TIG tacking using spacers and masking tape...

right after fillet brazing.. still quite hot >

after cooling slowly, the flux is soaked off with hot water >

a little bit of polishing... no problem.

hope you enjoyed the tour,

Paul