You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheelbuilding questions tips and ponderations

- Thread starter doctor-bond

- Start date

If the hub had drilled holes it might have been a whole lot easier maybe.I would suggest you unbuild one side and take the spokes out.

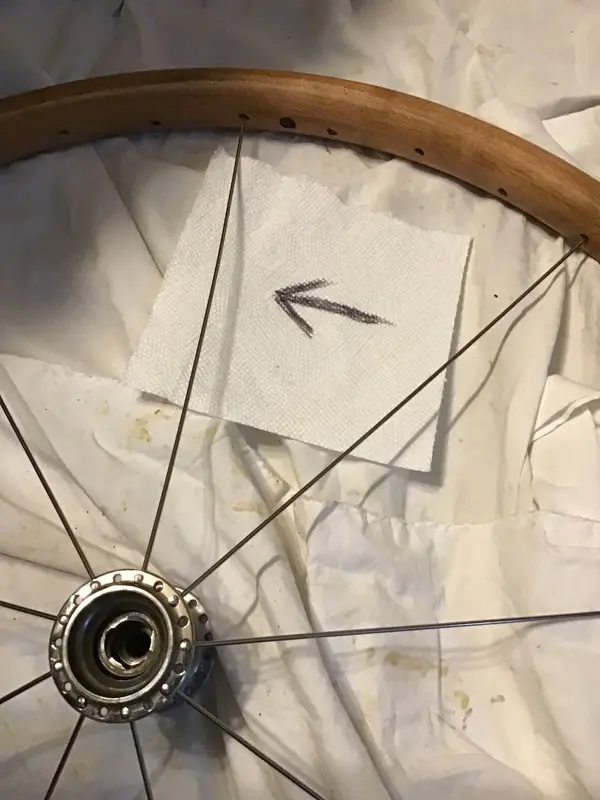

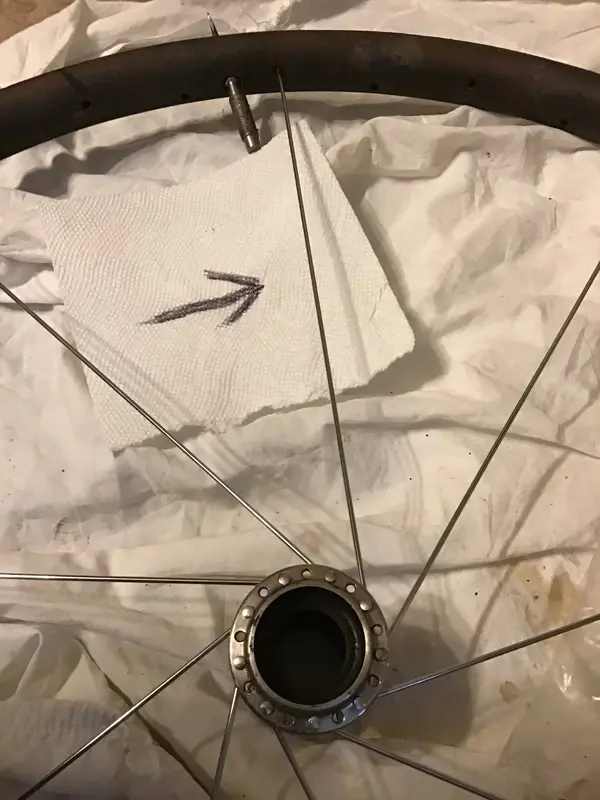

Look at the crossed pairs.

You need to notice that the spoke holes are out of phase with each other.

If you are inserting a trailing spoke, it starts at the spoke hole to the left (or right) of its opposite trailing number, and the nipple will fit in the corresponding left (or right) hole in the rim.

Basically the set of spokes on the 2 sides are identical, but one set is rotated 1/36 around!

I.e. the spoke holes correspond to the drilling on the rim.

This all needs to be considered before lacing.

If this is too condensed to understand, i would suggest you read a book on it.

Building wheels is simple enough, but there are a few geometric moves you have to make that aren't obvious to a novice. If you miss one, your equal spokes suddenly seem unequal!

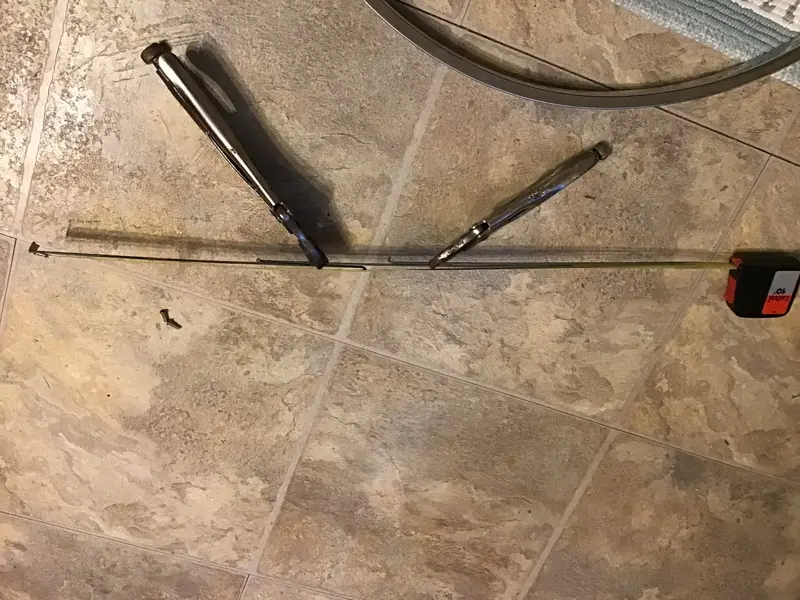

I went 3X crossed DS, 2X crossed NDS. NDS spokes poke out too much. The headout/inners are trailing on NDS. It didn't look as though The spokes were long enough for 3X.

Attachments

Good method but, problematic on thick spokes or small rims, as manoeuvring the other side inboard spokes means bending and forcing them though a sea of already crossed spokes.Massive Shraner lacing method fan here.

But it does have the advantage in letting you see the spoke pattern and length is issues early.

Horses for courses and personal opinion obv!

I've tried 3 cross nds but the spokes aren't close enough to be able to thread on the nipples.Are you sure they shouldnt be three cross nds, it would certainly explain why they are sticking out.

Although the entry angles on the eyelets look about right....but that's hard to really tell in a photo...

Ok. After a nights sleep.....

Did you say the hub flanges are different sizes? If so, stupid question, but you have got the right spokes in the right side!

Also you are crossing the right number on the right side? Could it be the drive side was 4x?

That combined with the wrong spokes on the wrong side would cause al kinds of problems.

Silly questions, but just to be certain!

Did you say the hub flanges are different sizes? If so, stupid question, but you have got the right spokes in the right side!

Also you are crossing the right number on the right side? Could it be the drive side was 4x?

That combined with the wrong spokes on the wrong side would cause al kinds of problems.

Silly questions, but just to be certain!

Last edited:

Also, the spokes you ordered did come back exactly the same length as those you took out? And...the measurement was correct from the old spoke?

Do you still have the old spokes? And any photo of the bike with the wheel in you can zoom in on?

Got to ask.

Do you still have the old spokes? And any photo of the bike with the wheel in you can zoom in on?

Got to ask.

The hub flanges do have different diameters. I have measured the spokes numerous times, there isn't much difference between them. As I understand, the number of times you cross the spokes is dictated by the number of spokes. In my case it's 36.Ok. After a nights sleep.....

Did you say the hub flanges are different sizes? If so, stupid question, but you have got the right spokes in the right side!

Also you are crossing the right number on the right side? Could it be the drive side was 4x?

That combined with the wrong spokes on the wrong side would cause al kinds of problems.

Silly questions, but just to be certain!