rmwesley

Retro Guru

Yeah, that’s the gold standard if you are buying one. I may or may not have borrowed a couple of ideas from them

Last edited:

Was going to get one but they wouldn’t take AmX or ship to Saudi when I was based over there so lost a customer…they are the Rolls Royce of wheel jigs but I d just ended up with a Park Tool one with a couple of DTI’sYeah, that’s the gold standard if you are buying one. I may or may not have borrowed a couple of ideas from themThey look the absolute dog’s dangly bits & the dials have a non-linear scale which makes them very user friendly. I’ve had a few goes one and, hand-on-heart, I can say I prefer mine though.

This one might be up your street… Lake and ElliotMy biggest gripe with most commercial truing stands is flex and repeatability. Always wanted to find a Hozan No. 330.

The "cleverest" bit is the adjustable clamping system for the wheel hub. The aluminium back plates provide the vertical movement. They are bolted onto the vertical posts using more of the "Roll-in T-Nut I-Type slot 8" fasteners.

The vertical posts can also be moved wider on the base itself if you are into building fat bike wheels, but I've not needed to do this yet.

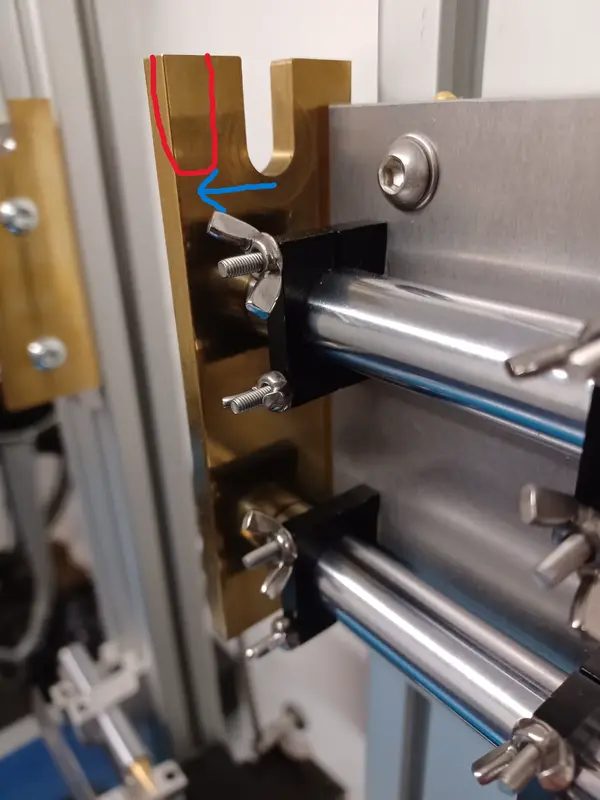

The shafts provide the horizontal movement. Very quick and easy to adjust if you are starting a different sized rim. The LHS shafts are shorter and remain semi-fixed. The RHS shafts are longer and are the ones I use to adjust for hub size. The shafts are 16mm precision shafts which can be picked online from various web sites, including motedis. Each shaft has got H8 (I think) holes machined in each end so the brass plates can be bolted onto them.

The brass plates have got "U" shaped slots in one end and and "V" slots in the other end just in case you need to accommodate a variety of weird hub axles.

The shafts are bolted onto the back plate with the black 16mm diameter mounts and wing nuts etc.

I can't remember the exact list of parts but the you should be able to see what is required from the pics.

View attachment 592708View attachment 592709View attachment 592710

Hi,Hi! Following up here, wondered if you remembered whether the aluminium plates and precision shaft diameter brackets were also from Motedis?

Hi,

The aluminium plates were just purchased from eBay or metals4u or somewhere similar. Just search for "custom size aluminium plate" and you should get plenty of options. Some places will even drill the holes for you if you don't have a drill press.

I'm fairly sure the brackets for the precision shafts were also eBay. Again just search for "16mm diameter pipe clamp black" and its then a case of trawling through the links till you find something suitable. I found the same item on aliexpress but haven't bought anything from there before, so up to you if you want to try it. Here is the link... https://www.aliexpress.com/item/1005007464218020.html

Good luck with the build. Happy to help further if you want any more pics / info etc.

Cheers, Richard