Factory Jackson

Retro Guru

- Feedback

- View

I've been chipping in on Mishmash69's thread (http://www.retrobike.co.uk/forum/viewto ... p;t=373677) on Kronos springs in Judys and other alternatives options.

I'd been toying with the idea of fitting more modern internals to the Judy chassis.

I was lead to this when stipping a set of SL's which the elastomer internals had turned to mush.

The availability of replacement elastomers and/or springs is proving more and more tricky.

This got me researching the posibility of fitting widely available springs from more modern models.

The Judy features a 28mm stanshion, so this lead me to the current XC28 fork which comes in a 80mm travel option - perfect.

Now bear in mind that modern forks feature a spring in one leg and rebound features in the other unlike the Judy which has spring/elasomers both side and a damper unit in the non-driveside leg (Judy DH has dampers in both however).

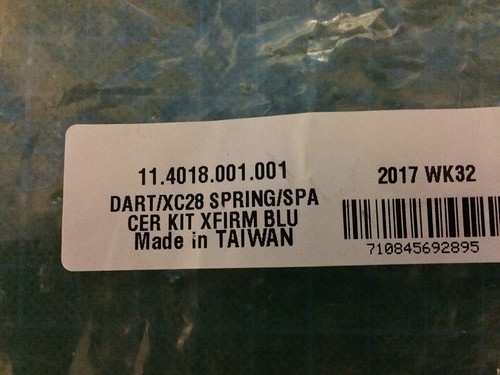

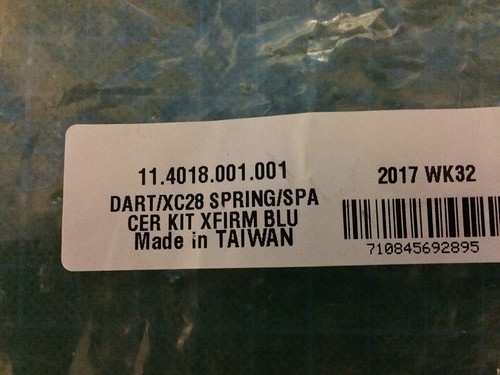

This is the kit I sourced. (note it is just the spring needed from the kit).

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

They can be found pretty easily via EBay or via retails such as here: https://total-sport.co.uk/rockshox-coil ... black.html

Taking out the current internals this is what we have to modify.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

The spring shown directly above is what I have been currently using replacing 5 of the elastomers. Its a pretty rough spring ripped out of an old set of RST forks.

Don't dwell on that too much, but you get the idea of the length of the compression stack that is fitted in a Judy.

Here we can see how the spring from the XC28 kit compares to the Judy set up. Lined up next to it is a spare 'dummy leg' kindly sourced via Longun (cheers buddy) as there was no going back if my plan didnt work :roll:

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

So the answer is to shorten the dummy shaft so the total length of the internal stack remains constant.

Below you'll see a black tape mark on the top dummy shaft on where to cut to. Dont worry, this was done more accurately than it looks by insersting the spring and top cap into the upper legs and with some digital verniers measuring the distance to where the housing for the dummy shaft sits (the black piece to the right handside on the dummy shaft).

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

It is also worth pointing out that i have kept a cut down elastomer sitting into the top cap which is short enough so it sits inside when wound full up.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

So, next was to shorten the shaft. Removing the required 52mm is the result shown here.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

Then all that is left to do is reassemble the fork.

Note that the spring has to be inserted from the bottom as it is too wide to pass through the threads at the top of the fork. The XC28 uses much thinner guage tubing but still with a 28mm outer.

And there we have it. The non driveside top cap has been put back in, but it serves no mechanical purpose.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on Flickr

Next thing i'm going to do is play around with the damper unit a bit. As it is dealing with a firm spring as opposed to elastomers (which have natural damping qualities as they return to full length) it is being asked to do a lot.

I'm going to try some different oil weights to see if I can slow things down a little.

So for less than £20 and about an hour of stipping/cutting/reasembling it is easy to upgrade from dead elastomers to something much more modern feeling.

Hopefully this is of interest.

cheers

Chris

.

I'd been toying with the idea of fitting more modern internals to the Judy chassis.

I was lead to this when stipping a set of SL's which the elastomer internals had turned to mush.

The availability of replacement elastomers and/or springs is proving more and more tricky.

This got me researching the posibility of fitting widely available springs from more modern models.

The Judy features a 28mm stanshion, so this lead me to the current XC28 fork which comes in a 80mm travel option - perfect.

Now bear in mind that modern forks feature a spring in one leg and rebound features in the other unlike the Judy which has spring/elasomers both side and a damper unit in the non-driveside leg (Judy DH has dampers in both however).

This is the kit I sourced. (note it is just the spring needed from the kit).

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrThey can be found pretty easily via EBay or via retails such as here: https://total-sport.co.uk/rockshox-coil ... black.html

Taking out the current internals this is what we have to modify.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrThe spring shown directly above is what I have been currently using replacing 5 of the elastomers. Its a pretty rough spring ripped out of an old set of RST forks.

Don't dwell on that too much, but you get the idea of the length of the compression stack that is fitted in a Judy.

Here we can see how the spring from the XC28 kit compares to the Judy set up. Lined up next to it is a spare 'dummy leg' kindly sourced via Longun (cheers buddy) as there was no going back if my plan didnt work :roll:

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrSo the answer is to shorten the dummy shaft so the total length of the internal stack remains constant.

Below you'll see a black tape mark on the top dummy shaft on where to cut to. Dont worry, this was done more accurately than it looks by insersting the spring and top cap into the upper legs and with some digital verniers measuring the distance to where the housing for the dummy shaft sits (the black piece to the right handside on the dummy shaft).

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrIt is also worth pointing out that i have kept a cut down elastomer sitting into the top cap which is short enough so it sits inside when wound full up.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrSo, next was to shorten the shaft. Removing the required 52mm is the result shown here.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrThen all that is left to do is reassemble the fork.

Note that the spring has to be inserted from the bottom as it is too wide to pass through the threads at the top of the fork. The XC28 uses much thinner guage tubing but still with a 28mm outer.

And there we have it. The non driveside top cap has been put back in, but it serves no mechanical purpose.

Untitled by FactoryJackson, on Flickr

Untitled by FactoryJackson, on FlickrNext thing i'm going to do is play around with the damper unit a bit. As it is dealing with a firm spring as opposed to elastomers (which have natural damping qualities as they return to full length) it is being asked to do a lot.

I'm going to try some different oil weights to see if I can slow things down a little.

So for less than £20 and about an hour of stipping/cutting/reasembling it is easy to upgrade from dead elastomers to something much more modern feeling.

Hopefully this is of interest.

cheers

Chris

.