MuchAlohaNui

Senior Retro Guru

Maybe @RockiMtn can confirm (if he wants of course). He's got an old Rocky Mountain Ti.CAn anybody confirm a Tibolt or alu Vertex/Edge seattube OD?

I will bet 31.60 -0+0.05mm for machining.

Maybe @RockiMtn can confirm (if he wants of course). He's got an old Rocky Mountain Ti.CAn anybody confirm a Tibolt or alu Vertex/Edge seattube OD?

I will bet 31.60 -0+0.05mm for machining.

both my aluminum frames are 31.8 od seat tube. Vertex and Thin Air. I can't help with a Ti-bolt.CAn anybody confirm a Tibolt or alu Vertex/Edge seattube OD?

I will bet 31.60 -0+0.05mm for machining.

I agree. Barrel nuts help a lot distributing tensions. But again we're in front of a design we want to keep original because of its retrobike value.Seat clamps with built-in threads are a flawed design. They all suffer from the bolt bending under torque a.k.a. Banana Bolt Syndrome. Not good.

Single-pivoting barrel nut seatclamps like the Salsa Lip-Lock are kinder on your frame's seat tube slit and also better for dropper posts than the above. However...

The absolute best seat clamp design on the market right now is the Pembree DBN. Dual-pivoting barrel nuts completely outclass even the single-pivoting barrel nut types like the Salsa.

https://pembree.com/dbn-seat-post-clamp/

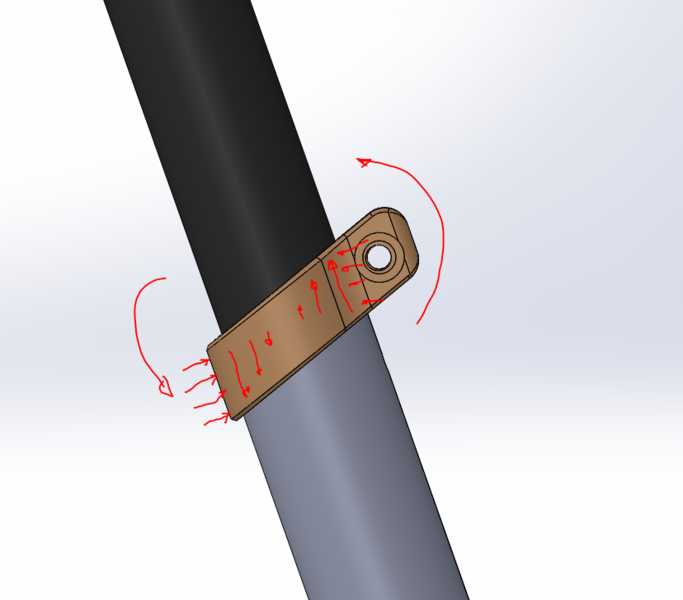

In my opinion, here pressure can not be equal in all surface because of tilted design. If it was equal, it would appear a force (torque) trying to rotate the clamp in XY plane, so I assume that most of pressure appears at both sides of the clamp, and pressure on front and rear is compensated with friction of both sides of the clamp with Seat tube to compensate the torque generated for not selfcompensated front/rear pressure.Stupid somewhat rhetorical, long-winded question: With any clamp, do you want the primary clamping force along the center line if the circumference of the clamp body, tangential and equal at all points along the inner surface? Seems to get past this the clamp would need more material overall with a higher torque rating.

Using the center axis of the tightening bolt (as the bolt is the means of providing the primary force), this then reduces the mechanical ability of the clamp to properly and uniformly pinch the seat tube to the seat post. Like you have a mechanism that utilizes static friction but due to the shape of the clamp and how much clamp is below the clamping bolt, a loss in static friction is realized because the bolt wants to sort of pull the material of the clamp upwards.

I am open to corrections of my limited physics background.

Interesting project.