Guinessisgoodforyou

rBotM Winner

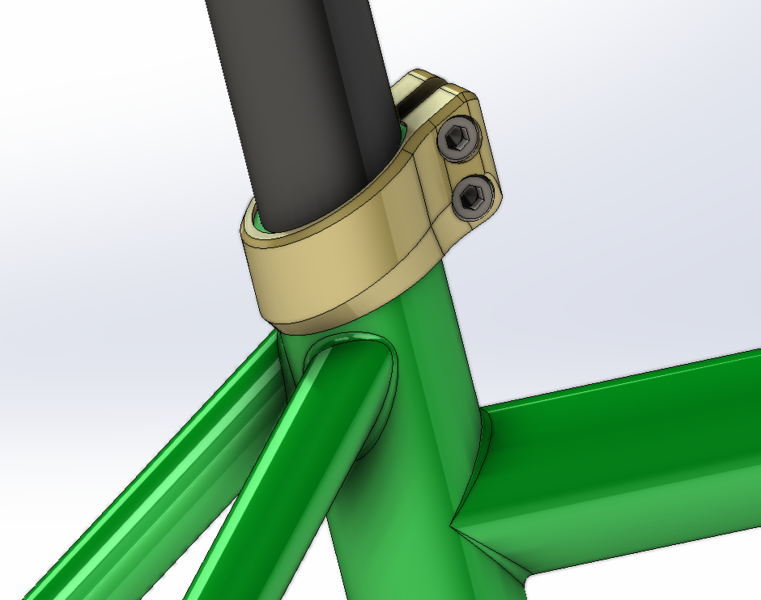

Perhaps you could make two? One for display like the original and a redesigned one for riding?No problem. But we're in a retrobike forum. We need to protect old designs sonetimes. This is a had design, but identifies the RM in early 90's. Im used to solve problems modifying things, but retro engineering needs to keep the design (changing materials, and only slightly the design keeping the essence). What Im looking to do. When you restore a retro bike, old car, etc you can not change to best design. Different objectives. No worries.