Definitely liking that shop alsoFollowing, love the workshop too.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Moulton Standard M1 1965 (finished)

- Thread starter rmwesley

- Start date

Kingswindsor

Dirt Disciple

@rmwesley That's great, thank you, I will follow up on that and Aldershot is not far from me. My neighbour has also recommended someone - I'll post back when I have more to say.Many thanks for the kind words.

My only experience is with Aurora Powder Coaters in Aldershot. I’ve had a few frames done by them and I think they are excellent. The cost for the frame, rear fork, front fork and rack came to £125, which I think is pretty competitive. They have a *lot* of work going through the shop so you can pretty much choose any palette colour you want, chuck in some sparkles, pearlescent effects etc.

Might be worth starting a thread asking for recommendations for somewhere local to you? I’d also figure out in advance how “fussy” you are in terms of the finish and state that upfront. If you want something which is 100% showroom perfect, it might involve a lot more time (& money) than something which is 99% perfect.

rmwesley

Retro Guru

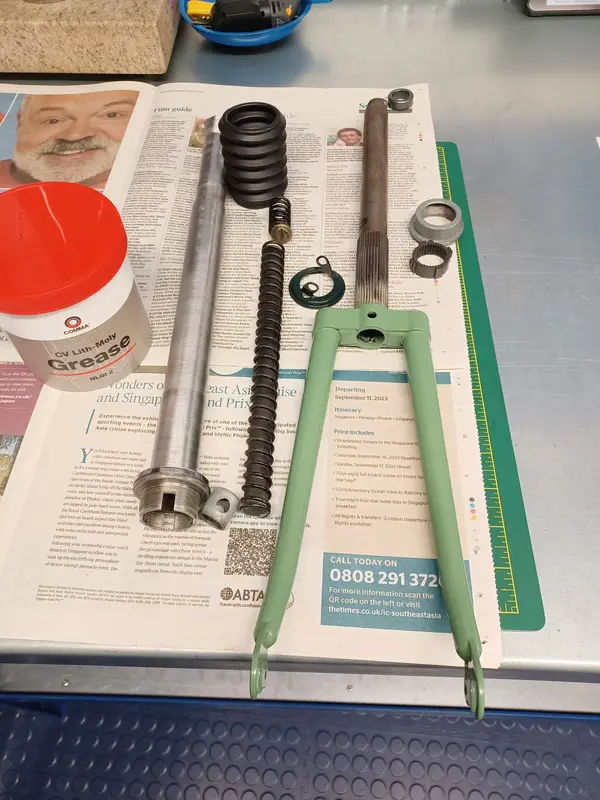

Next up was sorting out the front fork. Slight recap on the photo front first with varying stages of undress.

Unhook bellow from bellow retaining ring and pop out the retainer plug..

Extract compression spring and large amounts of congealed grease.

Reveal assembly which holds steerer tube and fork together.

Unscrew

Reveal more 60 year old grease.

Unhook bellow from bellow retaining ring and pop out the retainer plug..

Extract compression spring and large amounts of congealed grease.

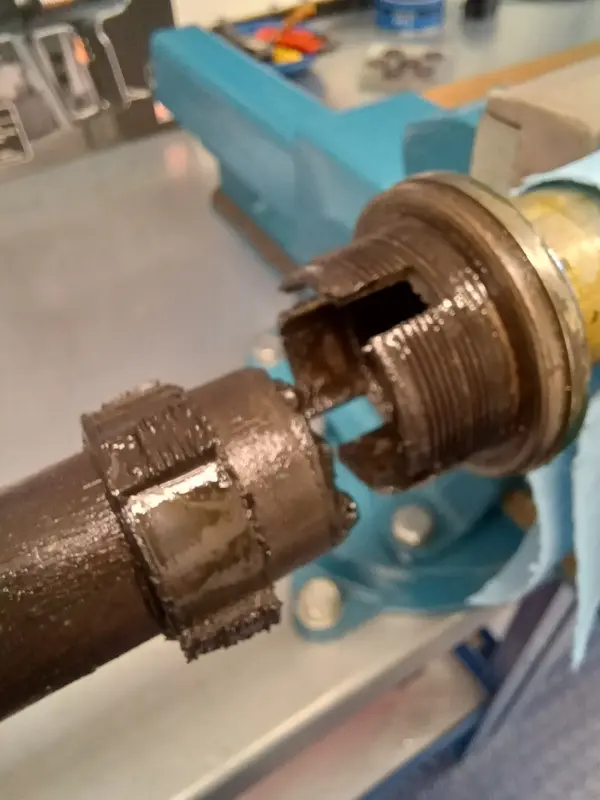

Reveal assembly which holds steerer tube and fork together.

Unscrew

Reveal more 60 year old grease.

rmwesley

Retro Guru

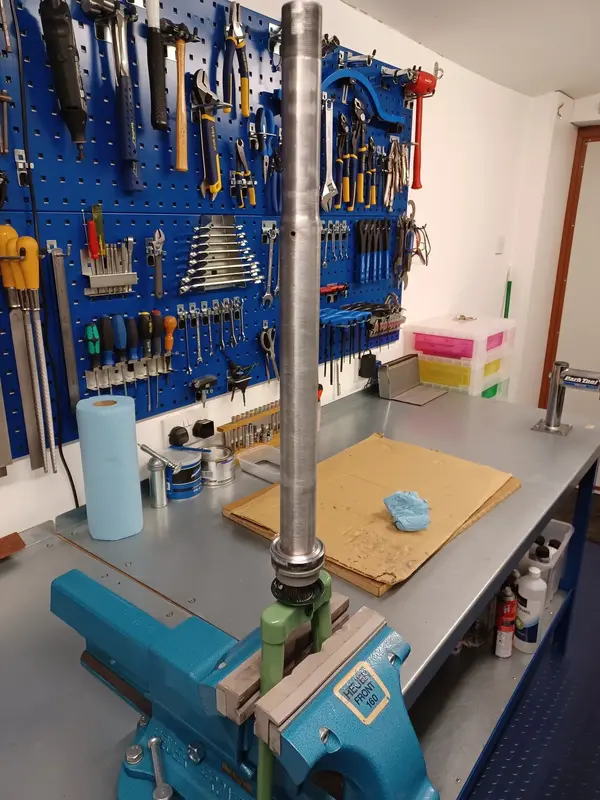

Re-assembly was another potentially sweary affair, since there is a rebound spring deep inside the inner steerer tube which is kept in place by a barrel nut (which needs to be held in place with a 30cm slot head screwdriver) whilst a bolt is lifted up through a blind hole to engage with it from the other end of the steerer tube with another 30cm Phillips screwdriver. Very badly explained. Picture might help. I was basically expecting this bit to take all day.

Bellows retainer and other bits in place. Note the nylon bearing at the top of the steerer tube. This needs to be a snug fit inside the outer steerer tube to avoid fork judder when braking. It is held in place with a tiny circlip.

Outer steerer tube screwed on.

Bellows on.

The tricky bit... A short rebound sprint is dropped down inner steerer tube followed by a retaining barrel nut with a slot head. All held in place with the screwdriver already in place. At the same time the carefully balanced nut is lifted up the other end of the steerer tube where they hopefully join together in beautiful harmony. Sounds easyish until you realise the bolt has to first navigate a narrow blind hole on its way up. Thought about using a bit of BluTack to hold the bolt on the screwdriver, but was too worried it would harden over time preventing the bolt from ever being removed again. So I didn't use any BluTack. To cut a long story short, I did it first time and it took about 30 seconds.

Finally, the elastomer and compression spring get dropped in followed by the retainer plug. Job done.

Bellows retainer and other bits in place. Note the nylon bearing at the top of the steerer tube. This needs to be a snug fit inside the outer steerer tube to avoid fork judder when braking. It is held in place with a tiny circlip.

Outer steerer tube screwed on.

Bellows on.

The tricky bit... A short rebound sprint is dropped down inner steerer tube followed by a retaining barrel nut with a slot head. All held in place with the screwdriver already in place. At the same time the carefully balanced nut is lifted up the other end of the steerer tube where they hopefully join together in beautiful harmony. Sounds easyish until you realise the bolt has to first navigate a narrow blind hole on its way up. Thought about using a bit of BluTack to hold the bolt on the screwdriver, but was too worried it would harden over time preventing the bolt from ever being removed again. So I didn't use any BluTack. To cut a long story short, I did it first time and it took about 30 seconds.

Finally, the elastomer and compression spring get dropped in followed by the retainer plug. Job done.

Last edited:

rmwesley

Retro Guru

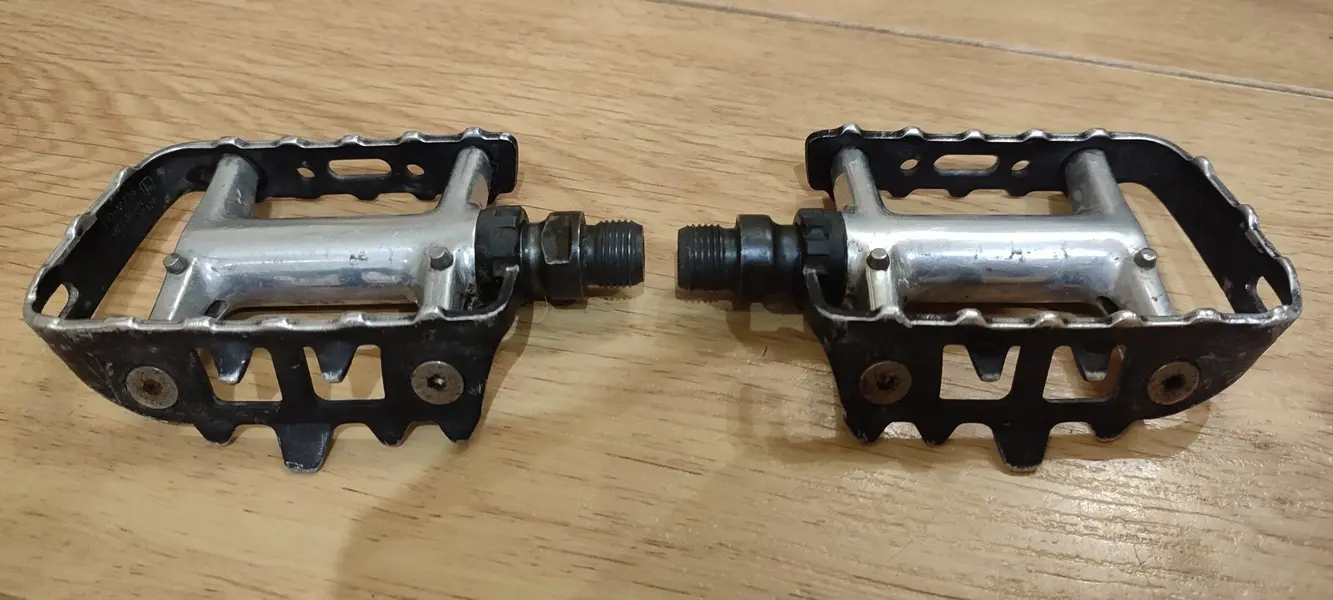

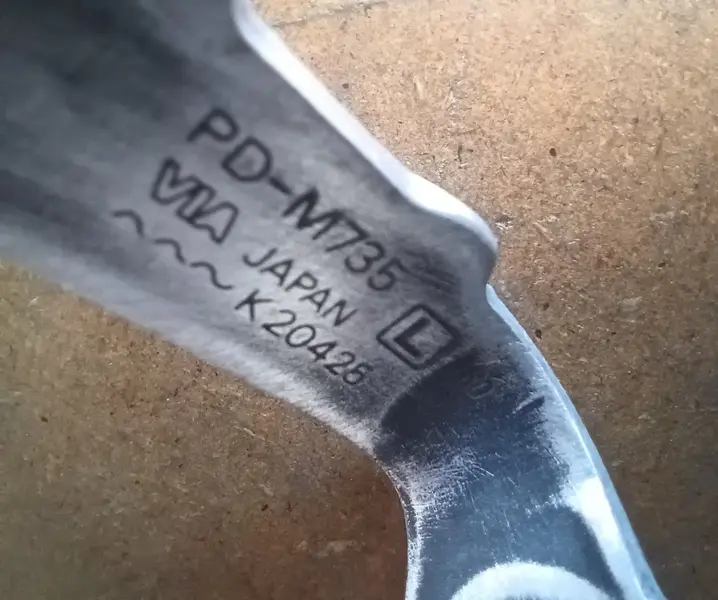

Haven't had a chance to do much lately, but got to work on the pedals today, which aren't the originals but a lovely pair of Deore XT M735 I picked up from @Fatal Swan a while back. They were already in pretty good shape so only needed a buff up.

Work in progress...

Work in progress...

Very nicely laid out shopTidied up a bit in the workshop. I'd love to be able to live with mess, but it just isn't meant to be.

View attachment 734875

rmwesley

Retro Guru

Another job ticked off  I was quite impressed with the paint, which will hopefully be tough enough to keep the pedals looking tidy for a bit. Meant to be used as an underbody coat with some level of chip resistance. Unfortunately the pictures don't do it justice since I sprayed on a varnish topcoat, just as the tree I was standing under decided to drop a ton of pollen. They did look much better before.

I was quite impressed with the paint, which will hopefully be tough enough to keep the pedals looking tidy for a bit. Meant to be used as an underbody coat with some level of chip resistance. Unfortunately the pictures don't do it justice since I sprayed on a varnish topcoat, just as the tree I was standing under decided to drop a ton of pollen. They did look much better before.

Gtpulse

Dyna-Tech Fan

Enjoying the Moulton work, something a bit different for me, never owned or even ridden one.Tidied up a bit in the workshop. I'd love to be able to live with mess, but it just isn't meant to be.

View attachment 734875

Please say your workspace is bikes only? My bike/diy/woodworking/hoarding space is about the exact opposite. Your cave looks so clean an EHO would let you prepare food in there!

Similar threads

- Replies

- 5

- Views

- 812