This bridges the 1998 cutoff but...

As far as I know, all of the Look Fournales bolt-on disc adapters were pre-ISO 2000. A few people have asked me about adapting the adapter...pre-2000 to ISO 2000. This is what I did:

Rough cut and filed 3.5mm from the inside face of the mounting tab, carefully. This places the inboard face of the mounting tabs 4mm outboard of the dropout face. The shape of the milling depends on your caliper mount. Mine is for a Hope Mono Mini #5 caliper direct to ISO without a postmount adapter, others are likely to be more straight across:

Unfortunately this leaves the mounting tabs only 3mm thick, not the ISO 6mm+ but it does work (At your own risk).

Also increase the chamfer on the bottom inside edge of the adapter to about 6mm at around 30 degrees. This stops the rotor boltheads from fouling.

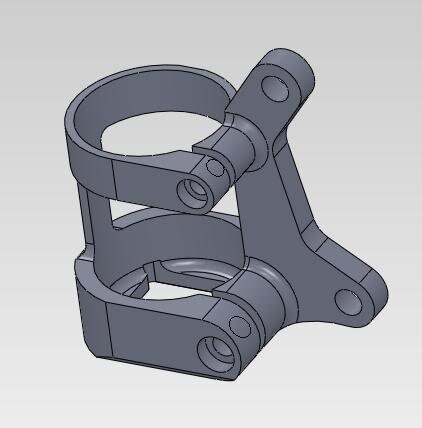

I've drawn up an ISO version of the adapter, with the mounting tabs rotated clockwise slightly for clearance and moved outboard:

But I think the whole thing could be designed a lot simpler, maybe two separate clamps around the leg and a bolted on mount bridging the two? What's the rotation risk?

Is there any interest out there for an ISO 2000 adapter? I'll farm around for some quotes if there's a demand. Otherwise, I'm happy to pass some untested CAD files around...dxf/STEP/IGES/SW etc. for CAM milling. Maybe even Laser Sintered RP, anyone?

Alternatively...if you're running a chunky caliper mount, like the cheaper Avid ones (rather than the finer forged or CNC milled ones):

it might be easier (and less risky) to just remove the thickness from around the mounting holes on that, and just chamfer the bottom of the (Hen's Teeth/Unicorn) Fournales part.

All the best,

As far as I know, all of the Look Fournales bolt-on disc adapters were pre-ISO 2000. A few people have asked me about adapting the adapter...pre-2000 to ISO 2000. This is what I did:

Rough cut and filed 3.5mm from the inside face of the mounting tab, carefully. This places the inboard face of the mounting tabs 4mm outboard of the dropout face. The shape of the milling depends on your caliper mount. Mine is for a Hope Mono Mini #5 caliper direct to ISO without a postmount adapter, others are likely to be more straight across:

Unfortunately this leaves the mounting tabs only 3mm thick, not the ISO 6mm+ but it does work (At your own risk).

Also increase the chamfer on the bottom inside edge of the adapter to about 6mm at around 30 degrees. This stops the rotor boltheads from fouling.

I've drawn up an ISO version of the adapter, with the mounting tabs rotated clockwise slightly for clearance and moved outboard:

But I think the whole thing could be designed a lot simpler, maybe two separate clamps around the leg and a bolted on mount bridging the two? What's the rotation risk?

Is there any interest out there for an ISO 2000 adapter? I'll farm around for some quotes if there's a demand. Otherwise, I'm happy to pass some untested CAD files around...dxf/STEP/IGES/SW etc. for CAM milling. Maybe even Laser Sintered RP, anyone?

Alternatively...if you're running a chunky caliper mount, like the cheaper Avid ones (rather than the finer forged or CNC milled ones):

it might be easier (and less risky) to just remove the thickness from around the mounting holes on that, and just chamfer the bottom of the (Hen's Teeth/Unicorn) Fournales part.

All the best,