You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hub/Drum Brake Bikes

- Thread starter GrahamJohnWallace

- Start date

Mickeyspinn

rBotM Winner

"The bike stayed with his wife after the divorce"

Ouch...

Some nice history here...the early days and bikes of ATB encompassed it all nowadays you need this bike for that,that bike for this, another variant for the other stuff with a few others for the more specialised stuff

Nothing glorious or rare but just dusting these off for a build,eBay bargains a few years ago for 50 Bob,new as well! 70mm sturmeys ,rear with 3 speed.

Ouch...

Some nice history here...the early days and bikes of ATB encompassed it all nowadays you need this bike for that,that bike for this, another variant for the other stuff with a few others for the more specialised stuff

Nothing glorious or rare but just dusting these off for a build,eBay bargains a few years ago for 50 Bob,new as well! 70mm sturmeys ,rear with 3 speed.

At least one BSB (Bell St Bikes) Blazer was made with front and rear hub brakes back in around 1986/7. It was made from 531 probably by Tom Board. It was owned by Nick who was the shop manager with Suntour gears, TA cranks and Sturmey Archer hubs.

Last I knew of it, it had been loaned to Mark Covell/Marc Floyd/Sky and allegedly stolen in 1987 or early 1988.

iirc a lot of Sturmey stuff at the time came from Fishers and it was virtually impossible to get so no more drum braked Blazers were built as far as I know..

Last I knew of it, it had been loaned to Mark Covell/Marc Floyd/Sky and allegedly stolen in 1987 or early 1988.

iirc a lot of Sturmey stuff at the time came from Fishers and it was virtually impossible to get so no more drum braked Blazers were built as far as I know..

- Feedback

- View

I believe that the Sturmey Archer alloy brakes were designed mainly for the Dutch-roadster market and they were never seriously marketed in the UK. However, a few UK MTB and City-bike makers experimented with them in the late 1980's. Meanwhile mainstream MTB design moved from using cantilevers to roller-cam brakes mounted under the bottom bracket. A development that was completely inappropriate for muddy UK conditions.At least one BSB (Bell St Bikes) Blazer was made with front and rear hub brakes back in around 1986/7. It was made from 531 probably by Tom Board. It was owned by Nick who was the shop manager with Suntour gears, TA cranks and Sturmey Archer hubs.

Last I knew of it, it had been loaned to Mark Covell/Marc Floyd/Sky and allegedly stolen in 1987 or early 1988.

iirc a lot of Sturmey stuff at the time came from Fishers and it was virtually impossible to get so no more drum braked Blazers were built as far as I know..

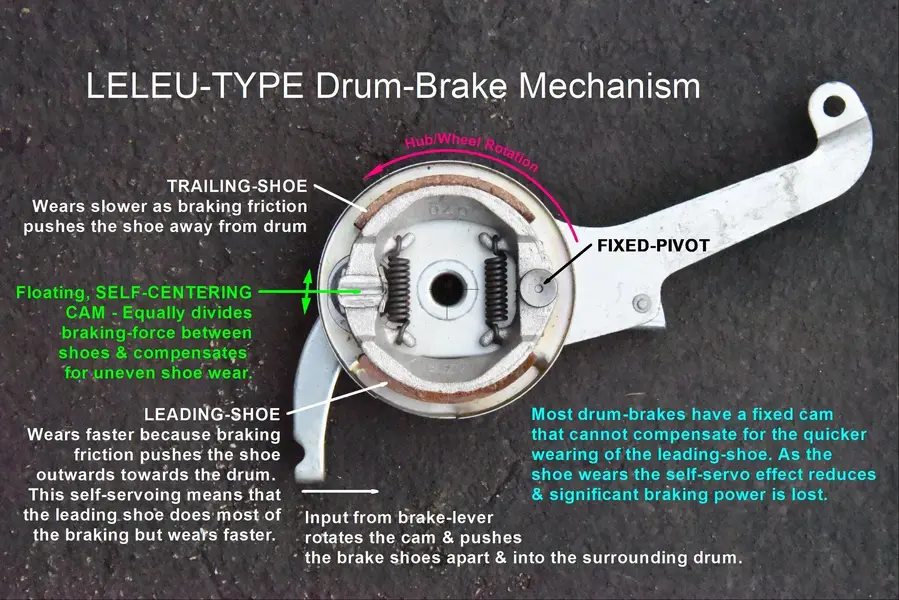

As far as I know, only Cleland and English-Cycles used Leleu type drum-brakes on their bikes. Though early on, Highpath re-engineered the Leleus by fitting sealed bearings, hollow axles, and Highpath made brake-plates, before going on to manufacture their 80mm Floating-Cam brakes. As far as I know, the Leleus were designed for use on tandems.

They say that a picture is worth a thousand words, so is my attempt at explaining why the Leleus were more powerful and reliable than other drum-brakes.

Last edited:

- Feedback

- View

The leading shoe is the one that has the self-servo self-energising action. In reverse, like when stopping on a steep ascent, the top shoe becomes the leading one. So with a Leleu-type brake you get the additional self-energising action no matter which way around the brake is applied. For off-road use you need to be able to easily hold the bike on a 45 degree slope.

This additional force is not about increasing the leverage (mechanical-advantage) applied to the brake-shoe from the brake-lever. It is an additional force like that of power-assisted car and motorcycle brakes, but with the additional force coming from the rotation of the wheel. Whilst the Leleus are specifically designed to exploit this additional source of energy, nearly all other bicycle drum-brake designs aren't. This is because, using a fixed cam means that the leading-shoe would need to pull away from its cam in order to self-energise. With a Leleu the floating-cam will move with the shoe.

Here is an article in which David Wrath-Sharman of Highpath Engineering explains the advantages of his 'Floating-Cam' brake.

http://www.63xc.com/dws/hubbrake.htm

This additional force is not about increasing the leverage (mechanical-advantage) applied to the brake-shoe from the brake-lever. It is an additional force like that of power-assisted car and motorcycle brakes, but with the additional force coming from the rotation of the wheel. Whilst the Leleus are specifically designed to exploit this additional source of energy, nearly all other bicycle drum-brake designs aren't. This is because, using a fixed cam means that the leading-shoe would need to pull away from its cam in order to self-energise. With a Leleu the floating-cam will move with the shoe.

Here is an article in which David Wrath-Sharman of Highpath Engineering explains the advantages of his 'Floating-Cam' brake.

http://www.63xc.com/dws/hubbrake.htm

- Feedback

- View

I used to think that the Repack down-hill races were named after hub-brakes, like the ones we have been discussing so far, getting so hot that the grease boiled out of the bearings. In fact the early MTB pioneers were originally using back-pedal coaster-brakes which were packed with grease to prevent wear on the all metal braking surfaces. Given the input force of a back pedal brake and the small diameter of the drums, it's not surprising that the grease had melted off by the time they reached the bottom.

Conventional hub-brakes use 'dry' high-friction brake-shoes that are pushed against the inside of a metal drum using the force form the handlebar levers. Users of these need to be careful not to get grease or oil onto the internal braking surfaces as this will destroy the braking friction. In comparison, grease filled drum-brakes need a much larger forces to create the required the braking friction .

Here's a video that explains how 'Repack' type back-pedal coaster-brakes work:

The back-pedal coaster-brake is a simple but elegant design. In 1990, Shimano's engineers set about revising the principle of the grease filled drum-brake as part of their Nexus project to design an all-weather, low-maintenance system for utility-bikes. In 1995 they introduced the INTER-M brake, now known as the Shimano Roller brake.

I have now been using Roller brakes for all weather mountain-biking for over 10 years. They are the quietest, smoothest and have the best modulation of any brake I have used. However, for my next project I intend to go back to using Leleus because they are lighter and more efficient.

Conventional hub-brakes use 'dry' high-friction brake-shoes that are pushed against the inside of a metal drum using the force form the handlebar levers. Users of these need to be careful not to get grease or oil onto the internal braking surfaces as this will destroy the braking friction. In comparison, grease filled drum-brakes need a much larger forces to create the required the braking friction .

Here's a video that explains how 'Repack' type back-pedal coaster-brakes work:

The back-pedal coaster-brake is a simple but elegant design. In 1990, Shimano's engineers set about revising the principle of the grease filled drum-brake as part of their Nexus project to design an all-weather, low-maintenance system for utility-bikes. In 1995 they introduced the INTER-M brake, now known as the Shimano Roller brake.

I have now been using Roller brakes for all weather mountain-biking for over 10 years. They are the quietest, smoothest and have the best modulation of any brake I have used. However, for my next project I intend to go back to using Leleus because they are lighter and more efficient.

Swallow were big fans of them in the mid 80s. My ptarmigan had mounts for both rear hub and rear/ front u brake on it. I ditched the rear and used the u brake in the end.

This was @Rod_Saetan Swallow Merlin with front and rear.....well i assume it was his!

https://www.retrobike.co.uk/threads/1989-swallow-merlin-xt-drum-brake.142839/

Lovely bit of kit.

This was @Rod_Saetan Swallow Merlin with front and rear.....well i assume it was his!

https://www.retrobike.co.uk/threads/1989-swallow-merlin-xt-drum-brake.142839/

Lovely bit of kit.

- Feedback

- View

With drum-brakes being popular on tandems, I am not surprised that a builder who made tandems would also use them on their MTBs.

This is what Rod says of the braking on his Swallow Merlin as: "Awful. On/off, little modulation, would work better with 4 finger levers Im sure, but I dont like 4 finger levers."

My own experience with the Sturmey's was, whilst they were ok for road riding, I wouldn't want to use them on a steep technical off-road downhill, even with four-finger levers.

This is what Rod says of the braking on his Swallow Merlin as: "Awful. On/off, little modulation, would work better with 4 finger levers Im sure, but I dont like 4 finger levers."

My own experience with the Sturmey's was, whilst they were ok for road riding, I wouldn't want to use them on a steep technical off-road downhill, even with four-finger levers.

Last edited:

Rod_Saetan

Old School Grand Master

- Feedback

- View

Yeah, it was a cool bike, but it had the stopping ability of the Exxon Valdez.

- Feedback

- View

Having said: "I wouldn't want to use them on a steep technical off-road downhill, even with four-finger levers." They never ever locked unexpectedly and threw me over the bars in the way that hydraulic disk-brakes have.

Nor can I remember a time when the Sturmey's + four finger levers, didn't eventually stop the bike. They just took their time.

Nor can I remember a time when the Sturmey's + four finger levers, didn't eventually stop the bike. They just took their time.

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 4

- Views

- 605

- Replies

- 35

- Views

- 4K