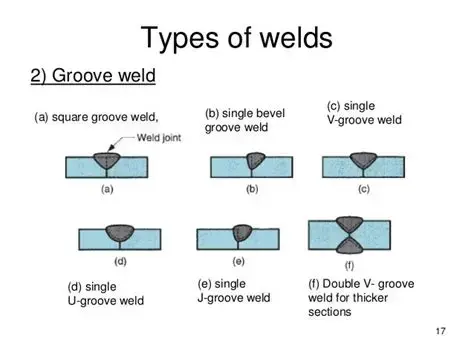

It was rather the V word in @novocaine answer that got me. I think I've already encountered it as V-cut. Is that the thing? And what exactly is a "V-cut"? How does it differ from a "normal" cut?^

The English "f" word being very technical of course.

The French "f" word is also equally very technical.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Frame failure experiences

- Thread starter bikeworkshop

- Start date

Oh - @novocaine does not mean "stitched" as in crochet or knitting.

novocaine

Retro Wizard

What he said.He means like how you would fill a crack in a wall with Polyfilla. It basically increases surface area for a key and to fill (and later smooth).

View attachment 937975

give it a go though.Oh - @novocaine does not mean "stitched" as in crochet or knitting.

bikeworkshop

Old School Grand Master

I've seen a frame stitched together with galvanised wire, little holes drilled each side of the break like this:

Sadly, before the days of smartphone, we often didn't have a camera handy to document the outer reaches of the bicycle repair world.

Sadly, before the days of smartphone, we often didn't have a camera handy to document the outer reaches of the bicycle repair world.

One of those mid 90s polished gts with oversized tubes iirc, crack running up the main tube from the bb weld

Sadly, before the days of smartphone, we often didn't have a camera handy to document the outer reaches of the bicycle repair world.

Sadly, before the days of smartphone, we often didn't have a camera handy to document the outer reaches of the bicycle repair world.One of those mid 90s polished gts with oversized tubes iirc, crack running up the main tube from the bb weld

Last edited:

Interesting Scrambler used 6106...that's a pretty soft mid-range alloy designed primarily for complex extrusions, rather than round tubing.

Even before welding, 6106-T6 has only 75-80% the tensile and Yield strength of 6061-T6. (UTS 250 vs 310 MPa, Yield 200 vs 270 MPa).

While 6061 is fairly hard to get hold of in Europe (It's a very US-based alloy), they could have gone for the widely available 6082-T6 instead, which has higher properties (295 UTS, 250 Yield) than 6106-T6.

Your cracked frame is repairable, though. I've done a few like that. 6106 is a 'heat treatable' alloy, so it will lose 50% of it's strength around a weld area. A repair in that area will not affect any other critical area of the frame.

The full post-weld heat treatment cycle, which can be pretty expensive. The cheapest I have found in the UK for a certificated process is £190 for a frame...OK for the Klein-owners out there, but probably not financially viable for your Scrambler.

6061-T6 (and presumably 6106) will naturally age harden a little (Nothing like as well as 7005/7020) back to the approximate properties of a T4 temper after a few months at room temperature, say 200 UTS 160 Yield.

This was a 6061 Azonic jump bike that I repaired several years ago. No post-weld heat treatment, since the client didn't want it, and considered it a non-critical area.

Cleaned back to good metal, de-greased inside, V-cut the crack:

Weld from initiation point to terminus, 4043 filler:

File back, fit a cover disc, weld and re-slot:

All the best,

Even before welding, 6106-T6 has only 75-80% the tensile and Yield strength of 6061-T6. (UTS 250 vs 310 MPa, Yield 200 vs 270 MPa).

While 6061 is fairly hard to get hold of in Europe (It's a very US-based alloy), they could have gone for the widely available 6082-T6 instead, which has higher properties (295 UTS, 250 Yield) than 6106-T6.

Your cracked frame is repairable, though. I've done a few like that. 6106 is a 'heat treatable' alloy, so it will lose 50% of it's strength around a weld area. A repair in that area will not affect any other critical area of the frame.

The full post-weld heat treatment cycle, which can be pretty expensive. The cheapest I have found in the UK for a certificated process is £190 for a frame...OK for the Klein-owners out there, but probably not financially viable for your Scrambler.

6061-T6 (and presumably 6106) will naturally age harden a little (Nothing like as well as 7005/7020) back to the approximate properties of a T4 temper after a few months at room temperature, say 200 UTS 160 Yield.

This was a 6061 Azonic jump bike that I repaired several years ago. No post-weld heat treatment, since the client didn't want it, and considered it a non-critical area.

Cleaned back to good metal, de-greased inside, V-cut the crack:

Weld from initiation point to terminus, 4043 filler:

File back, fit a cover disc, weld and re-slot:

All the best,

bikeworkshop

Old School Grand Master

A fun number now in the bikeworkshop recycling hopper:

Cracked right through the weld.

Dawes discovery, survived a decade on the mean streets.

While we are on Dawes, here's an illustration of why making unnecessary holes in your frame is unwise:

The water is pooling at the tube ends by the lug.

Failure is inevitable.

Cracked right through the weld.

Dawes discovery, survived a decade on the mean streets.

While we are on Dawes, here's an illustration of why making unnecessary holes in your frame is unwise:

The water is pooling at the tube ends by the lug.

Failure is inevitable.

bikeworkshop

Old School Grand Master

7Speed

Retro Guru

How many more people do you need to save from a trip to the hospital before you earn a free set of wrenches @bikeworkshop ?

bikeworkshop

Old School Grand Master

Sometimes it feels like youre just the messenger of bad news

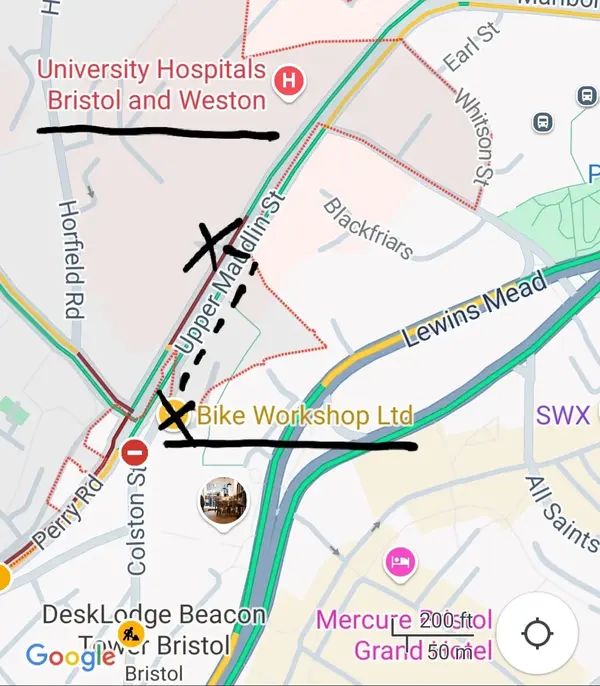

And as it's only about 250ft from our front door to the BRI, bristols main hospital, so we aren't saving them much of a trip.

Not sure i need any free wrenches , my guess would be that my home and work tool collection runs into several hundred kilos, ignoring the farming kit

We all love a good spanner though, full set of Würth ratcheting spanners in presentation pouch always on Santa's List.

And as it's only about 250ft from our front door to the BRI, bristols main hospital, so we aren't saving them much of a trip.

Not sure i need any free wrenches , my guess would be that my home and work tool collection runs into several hundred kilos, ignoring the farming kit

We all love a good spanner though, full set of Würth ratcheting spanners in presentation pouch always on Santa's List.

Similar threads

- Replies

- 0

- Views

- 361

- Replies

- 10

- Views

- 310

- Replies

- 16

- Views

- 2K