Retrorockit

Retro Guru

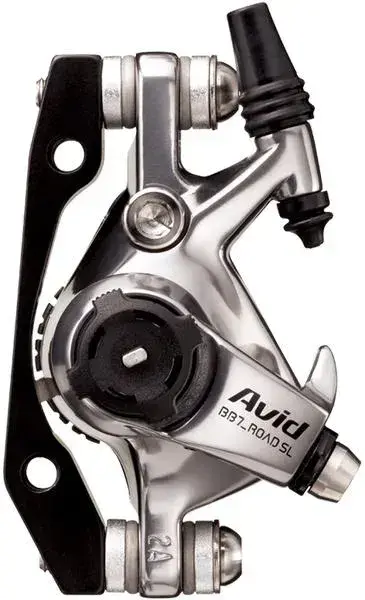

My 2004 Gary Fisher Solstice 26" comfort bike ahd Avid BB7s added to it when new. It's also had a 1500W motor a few years ago. The BB7s are still there. But the stress of the motor led me to a few upgradesthat I feel keep them on par with all but the be$t hydraulics. First off there are 2 series of BB7. The original AVID with small knobs, and the newer SRAM BB7 with larger knobs and an opening above the pads that the older ones don't have.

The first thing I do is run metallic pads. They never come with the brakes. But they cut way down on the frequency of brake adjustment ( about 5x) and last much longer. If you've run organic pads before, sand the rotors to remove the coating. I've found that in the rain they howl until the whole brake is wet then they settle down. But hey do work wet. Quality varies. I use SRAM. Off brand stuff will wear out your rotors. If you're ever stopping with BB7s and you need to increase pressure as you slow instead of backing off you need metallic pads.

Rotor size matters. I use offset sizes 185f/160r for 26". and 203/185 or 200/180 for 29". Skinny 770c tires I don't think it matters much. For the 26" Ebike it's 203/180.

Avid still offers their Speed Dial adjustable ratio levers in metal. The old 9.0 levers also had this and were all plastic. I use them on my XC bike. They protect the carbon handlebars.

Brake noise. I found that this happens under light braking when just one pad is touching. The rotor is free to ring like a gong. I found a solution, and it may be overkilll for most pedal bikes but it definitely makes the brakes run much cooler. Shimano Icetech rotors have an alloy rotor with stainless facings. This dampens any vibration. So no need to adjust for noise.They run 100*C cooler. Supposedly they won't work with BB7s. Just cut the extraction tab off of the inner pad. Removing the other pad first allows it to be pulled out easily. RT86 is the 6 bolt Icetech, RT76 looks the same but isn't.

For extreme use like loaded touring there are 220/223mm rotors and thicker rotors that he BB7 can open up to accept. But no Ictech option. Keeping the inner pad adjusted quiets them down.

BB7s get installed slightly off center. Read the manual when installing them.

Brake cable setup. BB7s will work with just about any thing for cables. But if you want them to feel as close to hydraulics as possible then you have some wrok to do.

1- Get good cables. Prestretched Stainless Steel, swedged smooth and round. Jagwire is one brand.

2- Get all extra slack out of the cable housings. When you pull the lever nothing should move except the brake lever, and the caliper arm. This can be tricky with internal cable routing. I've seen rear brake performance ruined by this.

3- High end cable housings. This is optional but fun for bodgers. You can get assorted compressionless cable kousings. But king of the hill is Jagwire Elite Link housing kits. SS cables as above, with a Teflon sheath, inside alloy beads for outer houisng. Tight bends are not a problem. Unfortunately this costs alomost as much as the brakes (but much less tha high end Hydros). One trick is to use 1/8"/3mm ID automotive metal brake line over the Teflon sheath for up the fork leg, or the seat stay for no compression, no slack housing. Alloy tubing can be found. The OD fits inside regular bicycle cable end ferrules. I've run it inside of the frame also. Shift cable can be done this way too.

If you get this far the BB7 has a little used return spring tension adjustment inside the caliper arm. You can adjust this until it balances the brake lever return spring. This gives much better feel of what the brake pads are doing.

4- Just for fun, the alloy cable beads come in different colors. You could match the bike , or even alternate different colors for a strobe effect that hydraulic brake hoses don't have.

So for no leaks, no bleeding, no water contaminated fluid, no popped pistons with the wheel removed, no boiled fluid when you least expect it. no melted plastic tubing at the caliper fitting......

The first thing I do is run metallic pads. They never come with the brakes. But they cut way down on the frequency of brake adjustment ( about 5x) and last much longer. If you've run organic pads before, sand the rotors to remove the coating. I've found that in the rain they howl until the whole brake is wet then they settle down. But hey do work wet. Quality varies. I use SRAM. Off brand stuff will wear out your rotors. If you're ever stopping with BB7s and you need to increase pressure as you slow instead of backing off you need metallic pads.

Rotor size matters. I use offset sizes 185f/160r for 26". and 203/185 or 200/180 for 29". Skinny 770c tires I don't think it matters much. For the 26" Ebike it's 203/180.

Avid still offers their Speed Dial adjustable ratio levers in metal. The old 9.0 levers also had this and were all plastic. I use them on my XC bike. They protect the carbon handlebars.

Brake noise. I found that this happens under light braking when just one pad is touching. The rotor is free to ring like a gong. I found a solution, and it may be overkilll for most pedal bikes but it definitely makes the brakes run much cooler. Shimano Icetech rotors have an alloy rotor with stainless facings. This dampens any vibration. So no need to adjust for noise.They run 100*C cooler. Supposedly they won't work with BB7s. Just cut the extraction tab off of the inner pad. Removing the other pad first allows it to be pulled out easily. RT86 is the 6 bolt Icetech, RT76 looks the same but isn't.

For extreme use like loaded touring there are 220/223mm rotors and thicker rotors that he BB7 can open up to accept. But no Ictech option. Keeping the inner pad adjusted quiets them down.

BB7s get installed slightly off center. Read the manual when installing them.

Brake cable setup. BB7s will work with just about any thing for cables. But if you want them to feel as close to hydraulics as possible then you have some wrok to do.

1- Get good cables. Prestretched Stainless Steel, swedged smooth and round. Jagwire is one brand.

2- Get all extra slack out of the cable housings. When you pull the lever nothing should move except the brake lever, and the caliper arm. This can be tricky with internal cable routing. I've seen rear brake performance ruined by this.

3- High end cable housings. This is optional but fun for bodgers. You can get assorted compressionless cable kousings. But king of the hill is Jagwire Elite Link housing kits. SS cables as above, with a Teflon sheath, inside alloy beads for outer houisng. Tight bends are not a problem. Unfortunately this costs alomost as much as the brakes (but much less tha high end Hydros). One trick is to use 1/8"/3mm ID automotive metal brake line over the Teflon sheath for up the fork leg, or the seat stay for no compression, no slack housing. Alloy tubing can be found. The OD fits inside regular bicycle cable end ferrules. I've run it inside of the frame also. Shift cable can be done this way too.

If you get this far the BB7 has a little used return spring tension adjustment inside the caliper arm. You can adjust this until it balances the brake lever return spring. This gives much better feel of what the brake pads are doing.

4- Just for fun, the alloy cable beads come in different colors. You could match the bike , or even alternate different colors for a strobe effect that hydraulic brake hoses don't have.

So for no leaks, no bleeding, no water contaminated fluid, no popped pistons with the wheel removed, no boiled fluid when you least expect it. no melted plastic tubing at the caliper fitting......