Ren Rawbor

Fat Chance Fan

Being a dog lover (and all round preferrer of animals over humans!) this post almost made me tear up, think I'm a bit over tired lol. That is so beautiful, loving the work so far & will continue reading tomorrow...I said a few posts ago that I hadn't made my mind up on the handle for this one;

View attachment 528639

As it turns out the decision came quickly and easily. I've had a bit of very old Oak set aside for something special for a while - my dog brought the Oak piece home from the forest with him one day, he'd been carrying it for about an hour. I'm guessing it'd been sat there for a very long time as whilst the outside was extremely weathered and rotten, the inside was incredibly dense, dry and rock hard. I'd been working on that blade in the days before he passed away.

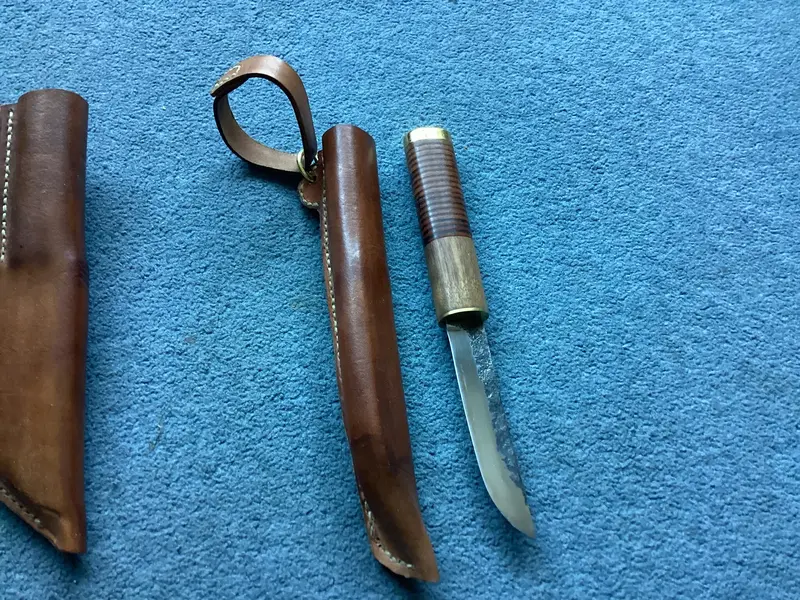

So I've spent a 'few' hours this week finishing it off. It's 15n20/1080 ladder damascus, the blade is 4" long, and 2.5mm thick. 9" total length. Copper pin and bolster, African Blackwood and Oak handle (Blackwood courtesy of Dyna-Ti; thanks matey!).

View attachment 528640View attachment 528641View attachment 528644View attachment 528645View attachment 528646View attachment 528649

It's the best I've made yet, I think. The photos don't quite show off the depth and pattern of the wood.

Hope you all like.