You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1996 GT LTS-2

- Thread starter Thias

- Start date

"Contra: Thinner tube. And the frame looses some of it's history." I agree.

Today it's sanding and polishing. I'm motivated now, but I already know that'll change after one and a half tubes...

So I have a fresh set of decals as a motivational.

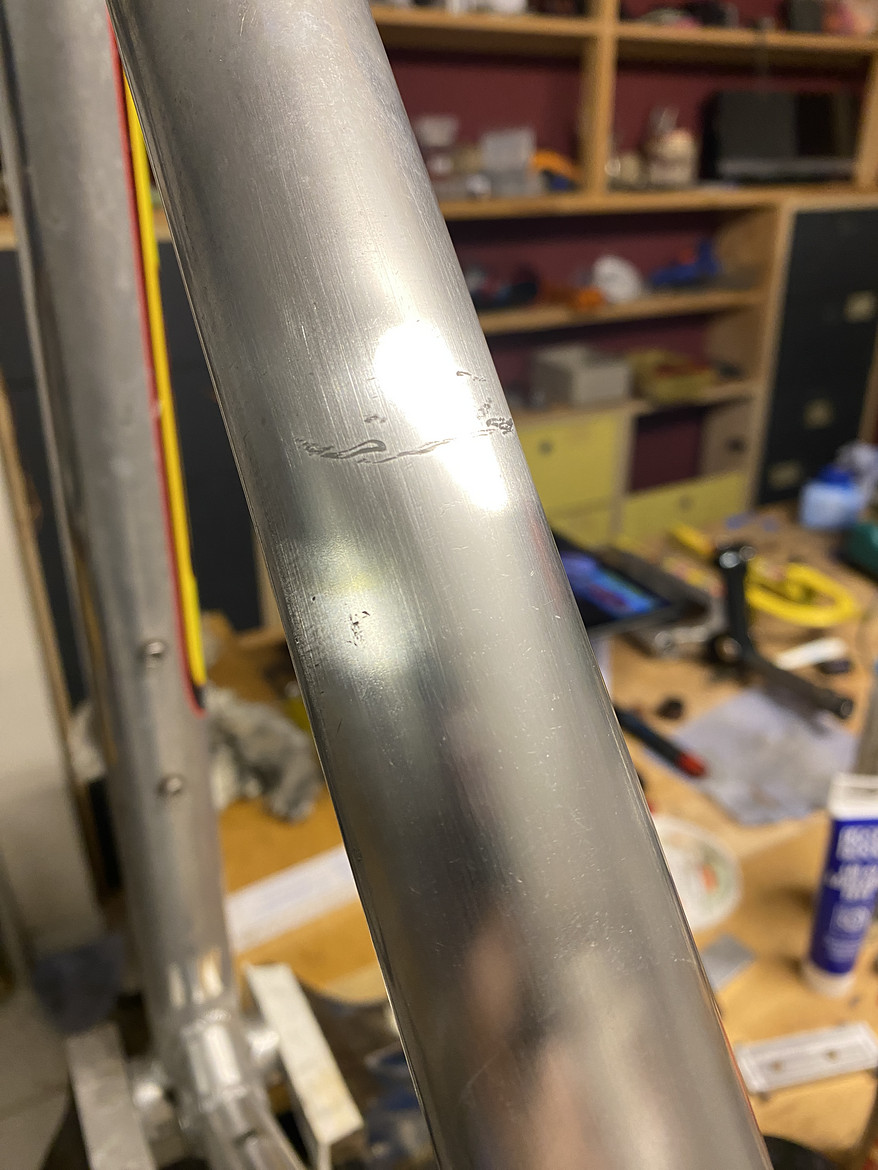

There is one deeper scratch on the top tube. What would you guys do? Sand it smooth or leave it?

Pro: Better looks

Contra: Thinner tube. And the frame looses some of it's history.

Hi there, nice job. I m with same job. How did you manage to put the bushings again on the inside? CheersOut comes the upper bushing. I have a makeshift tool, that I've been using for the last few years.

It did not make it this time though. The corrosion inside the casting was just too much and the puller plate bent while pulling the lower bushing. I guess I'll have to make another one.

I should be glad it was the plate that gave away and not the casting.

Now the "fun" part: using a reamer to scrape the corroded insides of the casting.

No. It's no fun at all. But I won't be able to put in the new bushing otherwise.

Hi Thias, this is a great thread. There is some skilled work gone into it so far. I am in the process of stripping my lots frame down. Please can you tell me how to remove the lower frame bushings and cones (above the bottom bracket)? I have removed the Allen head bout and the nut, but can not get the aluminium cones out.

How is the polishing going?

Thanks

How is the polishing going?

Thanks

Thanks for the reply. I thought this would be the case. Threads must be damaged in mine. The bolt just pushes straight through. I will have to come up with something else.One of the cones has a thread. You can use a bolt to pull that cone out. If it is seized, you can try and thread the bolt in from the opposite side, push or even us a hammer.

The polishing is... well.. let's say I got distracted

I can understand why you have got distracted, it is a laborious task! I have done a couple of sets of car wheels by hand in the past. Months of work!!

Similar threads

- Replies

- 3

- Views

- 717