WandsworthRouleur

Pace Fan

At nearly 80 and with a heart condition, my father has finally reconciled himself with the fact he’s not going to get on his Dyna-Tech 755 Ti racing bike anymore (he still uses his steel Thorn tourer), so hooked it out of the garage for me to add to my retro MTBs.

it‘s a little tired, covered in dust, mouldy bar tape and all the grease has solidified. Apart from that, it’s nearly immaculate. No paintwork damage, barely a scratch to the Ultegra 600 Tricolour group set, and mostly original. One of the resin stickers is missing (I’ve sourced some apparently NOS ones from Italy) and the tyres are fairly new Vittoria Rubino (in 25c — originally came with hard as steel 20c Michelin Hi-Lite Comps).

Here are some photos of it ‘as arrived’:

Original ITM quill stem and skinny bars:

Rear mech. Pretty sure that’s just dirt:

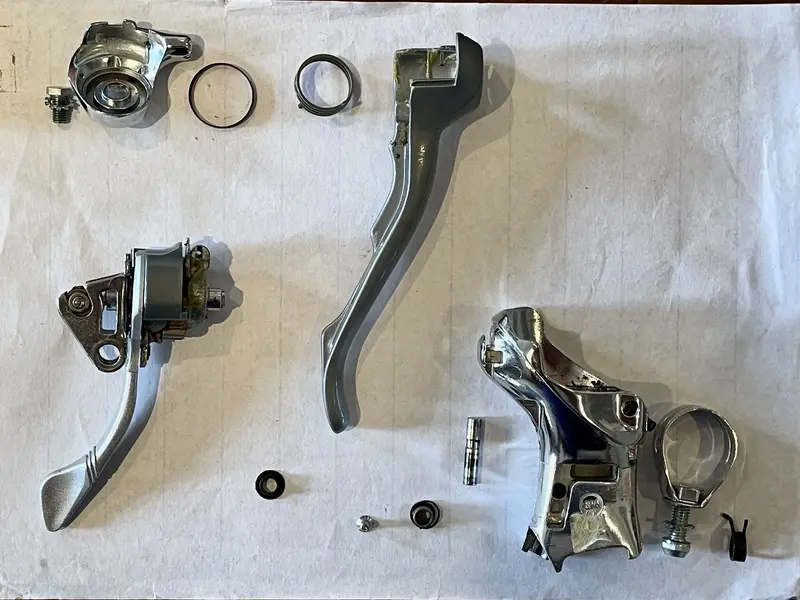

Front shifter minus the badge. Just needs a service and polish (all the internal grease has solidified):

Decals (above the lacquer) still in great condition:

Original Mavic Open 4CD rims showing barely any wear to the (ceramic?) coating:

According to the frame sticker, this was bought from Williams Cycles in Cheltenham, who seem to be still there, and still at the same address.

The original sofa-like Rolls saddle has been replaced by a Flite Titanium (good!), and the pedals are Ti spindle OnZa HOs. Not a typical choice for a road bike, but better for walking to the country pub bar and back! Apart from that, I could do with replacing the no brand crappy nylon bidon cage (Elite Ciussos have arrived), sorting out the bar tape, and finding some suitable tyres.

First step though… a proper clean.

it‘s a little tired, covered in dust, mouldy bar tape and all the grease has solidified. Apart from that, it’s nearly immaculate. No paintwork damage, barely a scratch to the Ultegra 600 Tricolour group set, and mostly original. One of the resin stickers is missing (I’ve sourced some apparently NOS ones from Italy) and the tyres are fairly new Vittoria Rubino (in 25c — originally came with hard as steel 20c Michelin Hi-Lite Comps).

Here are some photos of it ‘as arrived’:

Original ITM quill stem and skinny bars:

Rear mech. Pretty sure that’s just dirt:

Front shifter minus the badge. Just needs a service and polish (all the internal grease has solidified):

Decals (above the lacquer) still in great condition:

Original Mavic Open 4CD rims showing barely any wear to the (ceramic?) coating:

According to the frame sticker, this was bought from Williams Cycles in Cheltenham, who seem to be still there, and still at the same address.

The original sofa-like Rolls saddle has been replaced by a Flite Titanium (good!), and the pedals are Ti spindle OnZa HOs. Not a typical choice for a road bike, but better for walking to the country pub bar and back! Apart from that, I could do with replacing the no brand crappy nylon bidon cage (Elite Ciussos have arrived), sorting out the bar tape, and finding some suitable tyres.

First step though… a proper clean.