Same hereI absolutly love this!

I personally would have more chance of inventing a shrinking ray gun than doing this

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:4 scale Ritchey P20, this is going to take a while...

- Thread starter LumPi Panda

- Start date

LumPi Panda

Retro Guru

- Feedback

- View

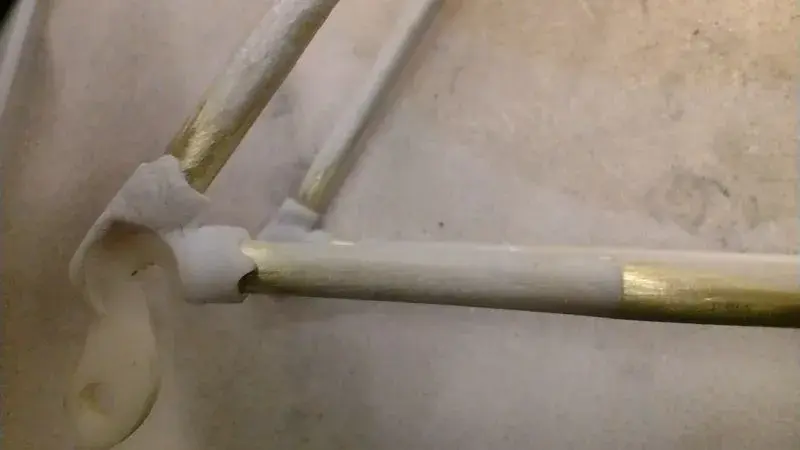

Spent lunchtime today cutting the little fluted bits in the dropouts. Not a spectacular amount of progress, but it's details like this that make the difference.

The dropouts are now glued on and the rear triangle feels loads more solid for it.

I've started thinking probably hubs next, and headset. I quite fancy the idea of getting the wheels in and having a "rolling chassis" to hang the rest of the bits on as the build progresses. Maybe a scale workstand is required...

The dropouts are now glued on and the rear triangle feels loads more solid for it.

I've started thinking probably hubs next, and headset. I quite fancy the idea of getting the wheels in and having a "rolling chassis" to hang the rest of the bits on as the build progresses. Maybe a scale workstand is required...

LumPi Panda

Retro Guru

- Feedback

- View

...and some tiny tools.

bikeworkshop

Old School Grand Master

5.5mm crank extractor? Fiddly.

I think the bike should be complemented with a full to-scale working toolkit.

There, I've said it now

I think the bike should be complemented with a full to-scale working toolkit.

There, I've said it now

LumPi Panda

Retro Guru

- Feedback

- View

Started work on the hubs over the weekend, and also dropped my phone from a height onto a flagstone floor. Thus, no photos of the rear hub going together.

Various bits of brass tube, laser cut Rowmark plastic flanges and filler to build up the profile. Rowmark is less brittle than acrylic so will hopefully be less prone to exploding when the wheel is laced. The axle is removable, probably unnecessarily.

The front hub is built in much the same way. The long silver bits end up as the end caps and axle for the front hub.

Various bits of brass tube, laser cut Rowmark plastic flanges and filler to build up the profile. Rowmark is less brittle than acrylic so will hopefully be less prone to exploding when the wheel is laced. The axle is removable, probably unnecessarily.

The front hub is built in much the same way. The long silver bits end up as the end caps and axle for the front hub.

LumPi Panda

Retro Guru

- Feedback

- View

LumPi Panda

Retro Guru

- Feedback

- View

...Safely returned from the Cairngorms. Had a truly spectacular time, thanks for asking.

Climbed through the cloud up Braeriach from Rothiemurcus, descended into Garbh Choire and spent the night there. Then walked out via the Lairig Ghru. Magical. Saw six people in three days, four of them were about a mile and a half away.

Now that I have finshed sorting through the photos and washing, I have been able to get the paint box back out.

Wheel building and cassette next I think...

Climbed through the cloud up Braeriach from Rothiemurcus, descended into Garbh Choire and spent the night there. Then walked out via the Lairig Ghru. Magical. Saw six people in three days, four of them were about a mile and a half away.

Now that I have finshed sorting through the photos and washing, I have been able to get the paint box back out.

Wheel building and cassette next I think...

Last edited:

baron von greenback

Retro Guru

That's some real good engineering there mate serious skill ever thought about taking orders

LumPi Panda

Retro Guru

- Feedback

- View

Thanks Baron.That's some real good engineering there mate serious skill ever thought about taking orders

I'd love to take orders, but I suspect that the probable cost and waiting times would scare most people away.

I've never properly added it up, but the Yeti build at a reasonable hourly labour rate, plus materials, would likely be similar money to the real one.

That's the problem with scratch built models, they just don't make good business sense unless you have clients with extremely deep pockets.

That's why pretty much the only viable scratch building companies make historic racing car models or have film studio/property developer budgets.

My day job is making architectural models, where a few grand on a model to sit in a sales office is a drop in the ocean of the budget for a full scale development of "luxury apatments" (flats) somewhere like London.

Either that or call it ART and quadruple the cost.

If anyone wants to prove me wrong, feel free to get in touch...

Similar threads

- Replies

- 11

- Views

- 1K

Latest posts

-

-

-

-

Raw bicycles! ROAR!!! The 'naked' no paint bicycle thread

- Latest: Mark south wales