You sure you don't just have giant hands holding a normal SID?!?Finally got around to spraying the stanchions.

I resprayed the crown too. The finish wasn't that great before, so I stripped it back and gave it more of a polish on the black base coat. One thing about the metal paint is that is shows up any surface imperfections horribly.

View attachment 916127

Just caps and dials to do now, then the first bit is finished...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:4 scale Ritchey P20, this is going to take a while...

- Thread starter LumPi Panda

- Start date

bikeworkshop

Old School Grand Master

LumPi Panda

Retro Guru

- Feedback

- View

Back again,

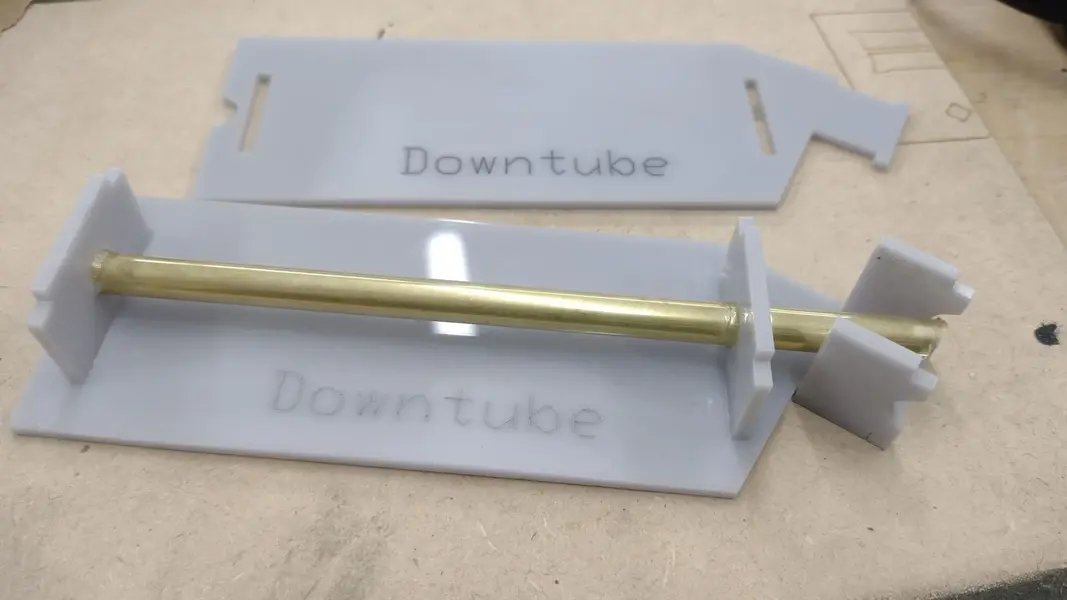

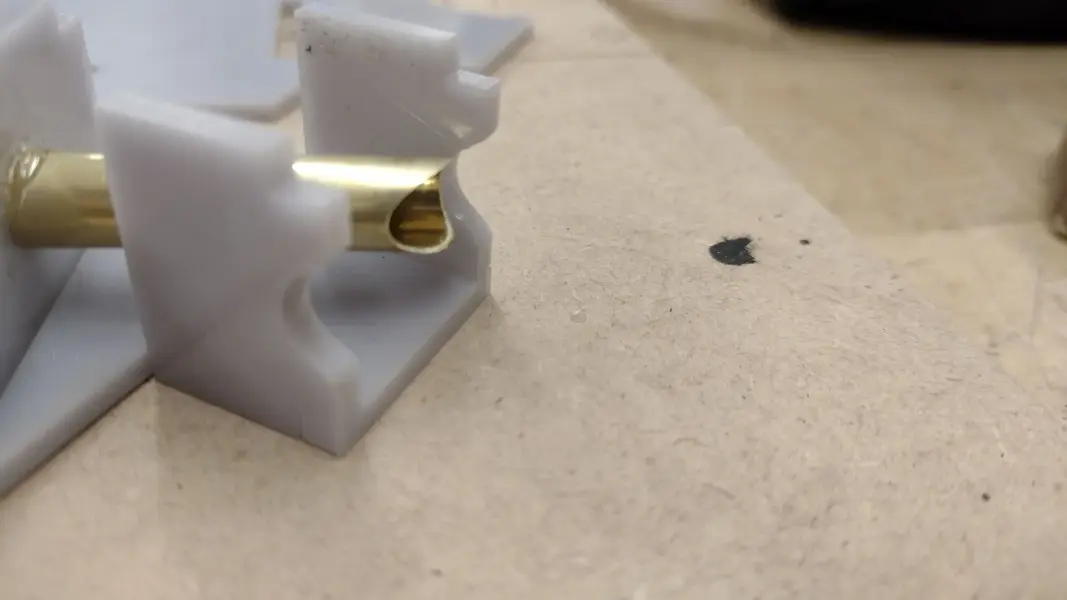

I've been puzzling out the frame and building loads of jigs.

Starting with the seat tube, which is slightly ovalised at the bottom bracket junction.

Mounting a bit of 9/32" brass tube into a couple of acrylic register blocks will help keep everything perpendicular when it needs to be...

...then some spacer blocks to fit the register blocks...

...which determine the dimensions of the ovalised bit when it's squeezed in a vice.

I've been puzzling out the frame and building loads of jigs.

Starting with the seat tube, which is slightly ovalised at the bottom bracket junction.

Mounting a bit of 9/32" brass tube into a couple of acrylic register blocks will help keep everything perpendicular when it needs to be...

...then some spacer blocks to fit the register blocks...

...which determine the dimensions of the ovalised bit when it's squeezed in a vice.

LumPi Panda

Retro Guru

- Feedback

- View

LumPi Panda

Retro Guru

- Feedback

- View

LumPi Panda

Retro Guru

- Feedback

- View

The tapered chainstays are made up of three different diameter brass tubes, one of which was ovalised in the vice and bent on a jig. Forgot to take pictures of that happening, but you can use your imagination.

This is the jig for drilling the position of the chainstay bridge...

... and then another for soldering it all together. The clear round acrylic block between the stays is hopefully enough clearance for the tyre later on.

There'll be another jig to cut the ends to fit the bottom bracket shell. I haven't done that bit yet.

This is the jig for drilling the position of the chainstay bridge...

... and then another for soldering it all together. The clear round acrylic block between the stays is hopefully enough clearance for the tyre later on.

There'll be another jig to cut the ends to fit the bottom bracket shell. I haven't done that bit yet.

Last edited:

LumPi Panda

Retro Guru

- Feedback

- View

What I have done is a jig to line up the front triangle. This might change to a modular jig including add on bits to hold the rear stays.

For now I'm just pleased that everything seems to fit so far.

Believe it or not, the trickiest bit was cutting the reinforcement rings for the headtube. They're only 1mm long and tended to wander about or deform when I was cutting them.

For now I'm just pleased that everything seems to fit so far.

Believe it or not, the trickiest bit was cutting the reinforcement rings for the headtube. They're only 1mm long and tended to wander about or deform when I was cutting them.

LumPi Panda

Retro Guru

- Feedback

- View

Front triangle soldered together, both sets of rear stays done too.

I've 3D printed the characteristic Ritchey dropouts. They'll be a little bit of fettling to get them right, but for now this will do in order to line up the rear triangle.

Dry fit of the dropouts.

The stays will be tapered with body filler after the whole thing is soldered together.

I must confess that I'm really chuffed with how it's coming together so far.

I've 3D printed the characteristic Ritchey dropouts. They'll be a little bit of fettling to get them right, but for now this will do in order to line up the rear triangle.

Dry fit of the dropouts.

The stays will be tapered with body filler after the whole thing is soldered together.

I must confess that I'm really chuffed with how it's coming together so far.

Similar threads

- Replies

- 11

- Views

- 1K