Top work on this! Great thread, I’ll keep an eye on this one  . I’ve seen a solution for the equidistant holes issue you’re having. I’ll need to find the Video though, can’t remember who did it? It was an thin aluminium disk mounted to the free end of the lathe center tube. The disk was marked out in 16 equal divisions (32 hole rim) around its circumference. Mag base block with a pointer on the top of the lathe. The guy just rotated the chuck by hand to each mark on the disk and drilled a hole. Hope that explanation is understandable? The lathe is a handy tool for sure, I had to make up an 1”-1 1/8” adapter kit for my WP Rond forks so I could fit them to my Fuchs. Your seat post qr skewer looks fantastic too! Keep up the good work

. I’ve seen a solution for the equidistant holes issue you’re having. I’ll need to find the Video though, can’t remember who did it? It was an thin aluminium disk mounted to the free end of the lathe center tube. The disk was marked out in 16 equal divisions (32 hole rim) around its circumference. Mag base block with a pointer on the top of the lathe. The guy just rotated the chuck by hand to each mark on the disk and drilled a hole. Hope that explanation is understandable? The lathe is a handy tool for sure, I had to make up an 1”-1 1/8” adapter kit for my WP Rond forks so I could fit them to my Fuchs. Your seat post qr skewer looks fantastic too! Keep up the good work

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rat Klein pinnacle build - Selfmade parts content!

- Thread starter Thias

- Start date

Thias

Klein Fan

I want to be able to turn the part clamped in the lathe by a fixed and repeatable degree. One way would be to print a scale and glue it to the lathe chuck. Then have a needle point to that scale and move the part by hand, somehow fix the chuck in place, then drill. The "fix the chuck in place"-part of it I will do. But I somehow didn't like the paper scale idea.

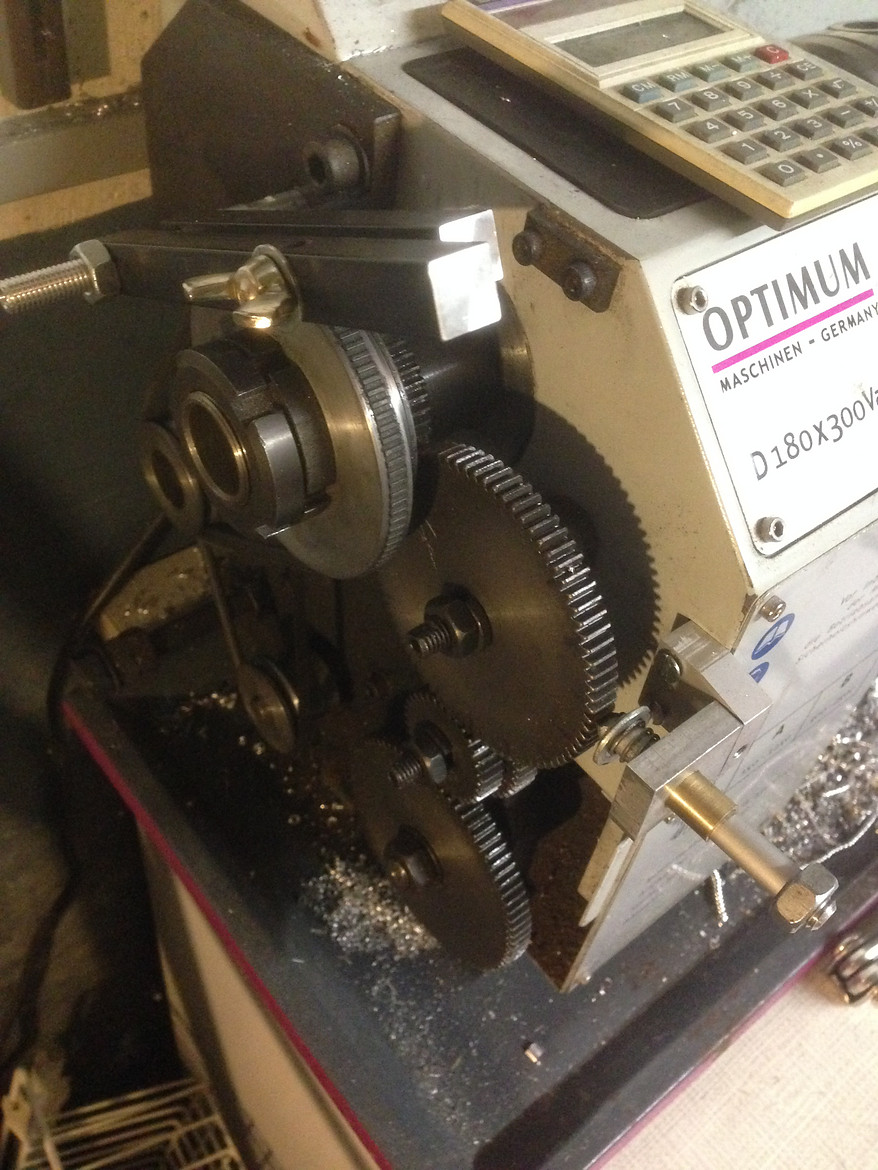

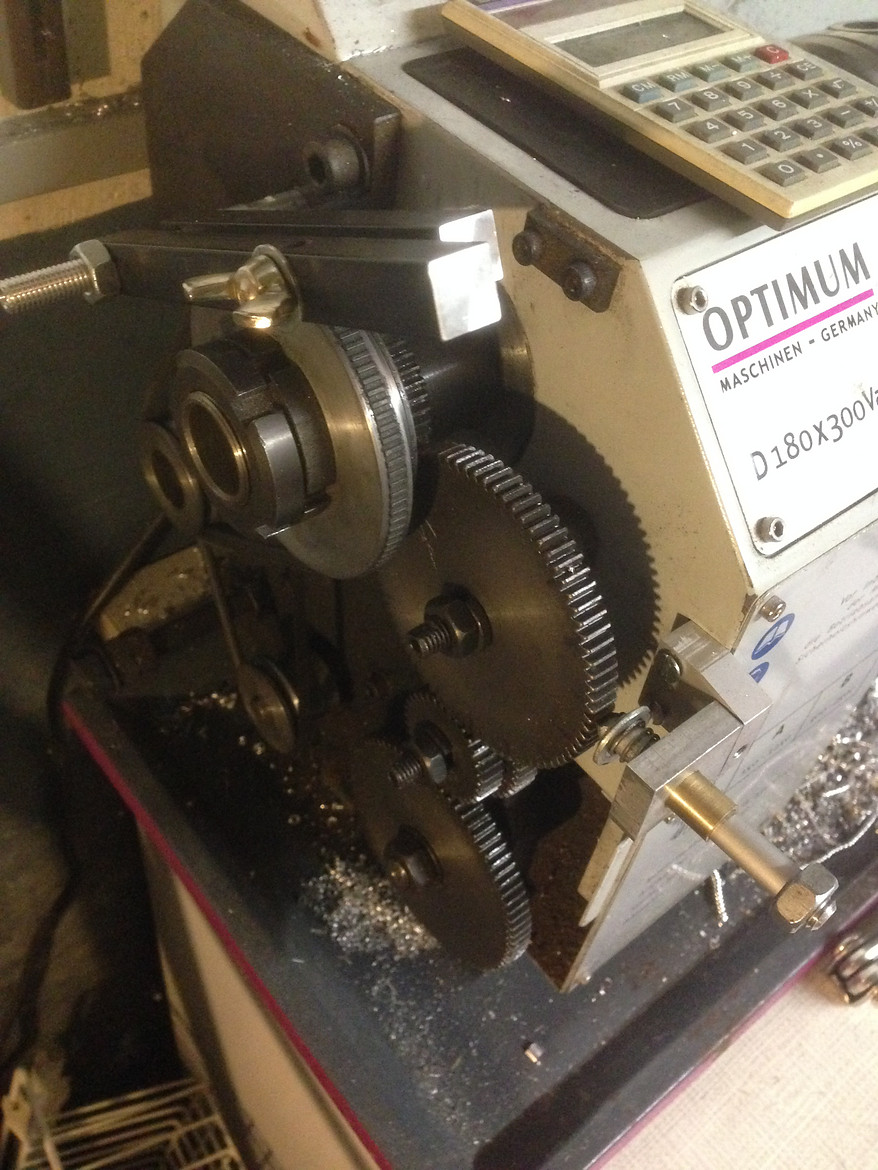

So let's take a look at the rear of the lathe. There is the main shaft (that is holding the chuck on the front) sticking out. It has a drivebelt for .. well... so it turns. And it also has a small ringear to drive the leadscrew. I won't go into detail about that. The important part here is, that there are interchangeable gears here, that are driven by the main shaft.

Or we can use these gears' teeth to count degrees. One tooth equals some amount of degrees. There is math involved. Devide 360° by the number of teeth... You get the gist of it.

Depending on the gear used you could, by counting teeth, get a repeatable degree of rotation on your part up front.

Now I had to make two "things" to make it all work.

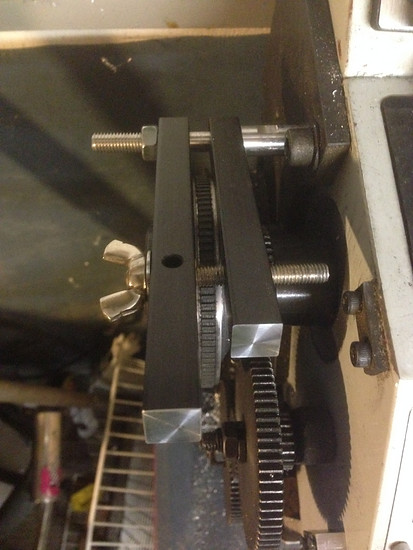

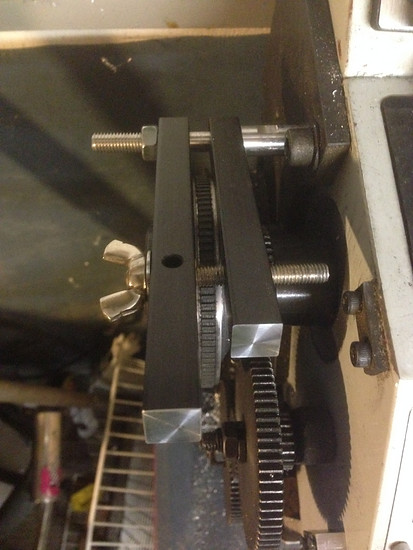

First a pin to count the teeth and second a clamp so the main shaft wouldn't move while drilling the part.

The "toothlocker" or counter:

Has a wedge shaped tip that is slightly off center. I can rotate the tip 180° to count "half teeth". And its also possible to lock the pin at some distance to the gear to allow normal operation of the lathe.

The shaft clamp..

Total:

And the first test piece:

I can work with that.

So let's take a look at the rear of the lathe. There is the main shaft (that is holding the chuck on the front) sticking out. It has a drivebelt for .. well... so it turns. And it also has a small ringear to drive the leadscrew. I won't go into detail about that. The important part here is, that there are interchangeable gears here, that are driven by the main shaft.

Or we can use these gears' teeth to count degrees. One tooth equals some amount of degrees. There is math involved. Devide 360° by the number of teeth... You get the gist of it.

Depending on the gear used you could, by counting teeth, get a repeatable degree of rotation on your part up front.

Now I had to make two "things" to make it all work.

First a pin to count the teeth and second a clamp so the main shaft wouldn't move while drilling the part.

The "toothlocker" or counter:

Has a wedge shaped tip that is slightly off center. I can rotate the tip 180° to count "half teeth". And its also possible to lock the pin at some distance to the gear to allow normal operation of the lathe.

The shaft clamp..

Total:

And the first test piece:

I can work with that.

Splatter Paint

Retrobike Rider

- Feedback

- View

Great thread!

Thias

Klein Fan

Back on the Hope hub.

New flange in the making.

Result!

I used new bearings and seals, this hub is ready to go again.

All though not on this build. It is just too cute. It's tiny!

Meanwhile, I got these absolutely humongous rims in the mail. They were for a fat bike originally, I think.

I really like them. They are going on the bike!

New flange in the making.

Result!

I used new bearings and seals, this hub is ready to go again.

All though not on this build. It is just too cute. It's tiny!

Meanwhile, I got these absolutely humongous rims in the mail. They were for a fat bike originally, I think.

I really like them. They are going on the bike!

Last edited:

Frankenorange

Orange 🍊 Fan

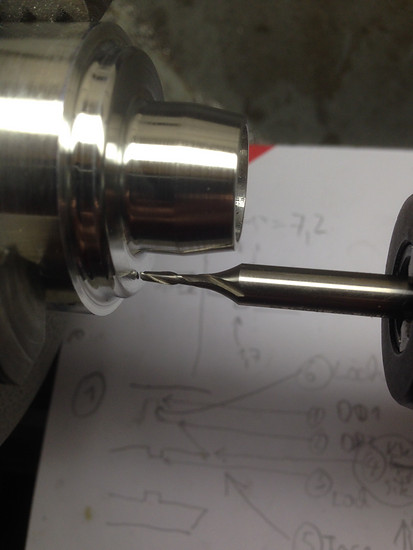

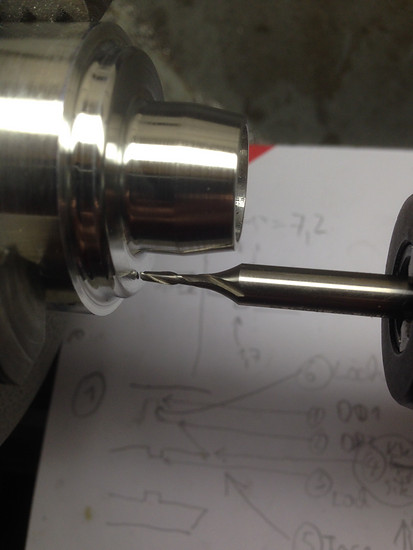

Awesome! Can you please take a pic of what is going on at the drill end of things.

Frankenorange

Orange 🍊 Fan

Hm? Drill end? I thought I did that?

There is a pic of the drill, in a collet chuck, but i would like to see how it is powered. Assuming it is some kind of powered head mounted on the cross slide, or something.

doctor-bond

Feature Bike

Top skills.

Similar threads

- Replies

- 79

- Views

- 5K

- Replies

- 34

- Views

- 5K

- Replies

- 52

- Views

- 3K