I finally got some Hope C2 brakesets with Pro levers, some in better, some in worse shape and all the spare parts, tools and extras I need to start their complete rebuild. I read loads about rebuilding and bleeding them in the original manuals and forum posts and watched all youtube videos on these brakes which I could find, but have never actually done any of these procedures, so some questions still remain and I'd be grateful if anyone with experience could help me out on one or two. Many thanks in advance!

1) How do I get rid of the orange-brown residue inside the brake calipers?

The two calipers I already opened have some kind of orange-brown residue (from oxidation?), almost like a film, inside and a noticeably different feel to the touch than the actual aluminium, looking like this in the open caliper on the left in the video:

(from 2:30 in the caliper on the left)

Another youtuber gets rid of it with a brake and parts cleaner from a brand called Carlube:

(around 6:30)

With my brake and parts cleaner I had no success though and can't get Carlube here. Which other cleaners or methods do the trick?

2) Are there any recommendations on completely bleeding a drained system?

I couldn't find any details but there seems to be consesus that this is a major headache. However, I have to rebuild levers, calipers and install completely NOS and empty hoses, so there is no way around it.

Maybe with a syringe from the bottom?

3) At the end of the bleeding procedure, how do I install the the master cylinder cap together with the reservoir piston correctly?

The original manuals (https://www.hopetech.com/_repository/1/documents/hopeman1-1.pdf and https://www.hopetech.com/_repository/1/documents/userguide_printed_2002-1.pdf) seem to imply screwing the master cylinder cap in first and then screw the adjuster anti-clockwise:

"10. Place the reservoir piston into the master cylinder and allow the fluid to overflow. Gently push it down until it rests on the ‘O’ ring seal and clean away the excess fluid.

11. Screw the silver adjuster into the piston (note, this is a left hand thread and is part of the master cylinder cap) until the cap makes contact with the top of the master cylinder. Press gently down on the cap and thread it clockwise until it is tight then tighten with a 26mm spanner. Screw the thumbwheel of the adjuster (item 25) anti- clockwise to the limit of its travel."

While a website called Hope FAQ (https://www.oocities.org/ti_guy.geo/hope_faq.html) says to do that simultaneously:

"Now take the reservoir cap and piston assembly, which you have already pre-adjusted earlier, and carefully insert the piston into the reservoir and slowly tighten the cap while simultaneously screwing the pad adjuster counter-clockwise."

Any recommendations which works better or at all? If done simultaneously, do I just hold on to the pad adjuster while screwing in the master cylinder cap, thereby making it actually move counter-clockwise at the same time, or do I need to actively screw into the opposite directions?

4) After that, what is the best procedure to eject enough but not too much excess fluid in the system?

From forum posts I gather many folks struggle with that.

The Hope manual says to just open the bleed nipple and let the caliper retract without further details:

"Open the bleed nipple a 1/4 turn to allow the pistons to retract into the caliper. The pistons are spring loaded and should return on their own but may require manually pressing back."

The Hope FAQs go into much more detail:

"When the reservoir cap is screwed completely tightened, the caliper pistons may be extended such that the pads are touching. In order to open the pads, loosen the bleed nipple screw until just a drop of fluid is released from the bleed tube (this is why we left the hose still attached). You may have to turn the adjuster knob clockwise just a little bit to get enough fluid to come out. Do this only until you have enough clearance between the pads to put the wheel/rotor back in place to run drag free."

Is this the way to go or is there a better method?

5) Can I install a 6 mm braided Hope hose with the original hydraulic fittings by installing the 6 mm olive right around the outer plastic skin and then screw it together?

I originally came across this youtuber who seems to know a lot about Hope brakes who does it exactly like that (

).

But then I found that when Hope came out with their own braided hoses they sold these together with the then new 5 mm olive and new 5mm hydraulic fittings right from the start:

For this, I figure one has to strip the outer plastic skin before installing the 5 mm olive right on the metal braids, otherwise the smaller olive won't fit.

Any experiences whether one method (plus parts) is better than the other? I'd favor less tinkering so would be happy to skip skinning the hose first.

6) Is there a way to get rid of the lateral play of the Pro levers?

Every set of Pro levers I got has a little play laterally when squeezing the lever, right before I feel that the lever actually presses on the piston. While with some levers I found some play between the lever and the brass barrel in the middle (1 and 12 on the diagram https://www.hopetech.com/_repository/1/documents/ClosedProleverExpview-1.pdf), all levers seem to have some play between the round end of the adjuster screw and the top of the piston (9 and 4).

Any way to get rid of that or is there even another reason for this play?

7) Should I use the "new" upper piston seal or source it from the Sport version?

The upper piston seal currently sold by hope doesn't really look like the one installed in my levers.

The new upper seal sold by Hope closely resembles the lower one, a bit like a plate with some hollow section at the bottom (sorry for my English - can't really describe it accurately): https://www.sjscycles.co.uk/brake-l...der-seal-kit-complete-pro-hbspc59pro/?geoc=AT

In the two levers I already disassembled though, the upper one has a ring shape, as pictured in the Hope diagram (7 in the diagram https://www.hopetech.com/_repository/1/documents/ClosedProleverExpview-1.pdf).

Interestingly, it looks more or less exactly like the upper piston seal still sold by Hope for the Sport levers https://www.sjscycles.co.uk/brake-l...seal-kit-complete-sport-hbspc59sport/?geoc=AT

Any experience if one of these is better to install?

1) How do I get rid of the orange-brown residue inside the brake calipers?

The two calipers I already opened have some kind of orange-brown residue (from oxidation?), almost like a film, inside and a noticeably different feel to the touch than the actual aluminium, looking like this in the open caliper on the left in the video:

Another youtuber gets rid of it with a brake and parts cleaner from a brand called Carlube:

With my brake and parts cleaner I had no success though and can't get Carlube here. Which other cleaners or methods do the trick?

2) Are there any recommendations on completely bleeding a drained system?

I couldn't find any details but there seems to be consesus that this is a major headache. However, I have to rebuild levers, calipers and install completely NOS and empty hoses, so there is no way around it.

Maybe with a syringe from the bottom?

3) At the end of the bleeding procedure, how do I install the the master cylinder cap together with the reservoir piston correctly?

The original manuals (https://www.hopetech.com/_repository/1/documents/hopeman1-1.pdf and https://www.hopetech.com/_repository/1/documents/userguide_printed_2002-1.pdf) seem to imply screwing the master cylinder cap in first and then screw the adjuster anti-clockwise:

"10. Place the reservoir piston into the master cylinder and allow the fluid to overflow. Gently push it down until it rests on the ‘O’ ring seal and clean away the excess fluid.

11. Screw the silver adjuster into the piston (note, this is a left hand thread and is part of the master cylinder cap) until the cap makes contact with the top of the master cylinder. Press gently down on the cap and thread it clockwise until it is tight then tighten with a 26mm spanner. Screw the thumbwheel of the adjuster (item 25) anti- clockwise to the limit of its travel."

While a website called Hope FAQ (https://www.oocities.org/ti_guy.geo/hope_faq.html) says to do that simultaneously:

"Now take the reservoir cap and piston assembly, which you have already pre-adjusted earlier, and carefully insert the piston into the reservoir and slowly tighten the cap while simultaneously screwing the pad adjuster counter-clockwise."

Any recommendations which works better or at all? If done simultaneously, do I just hold on to the pad adjuster while screwing in the master cylinder cap, thereby making it actually move counter-clockwise at the same time, or do I need to actively screw into the opposite directions?

4) After that, what is the best procedure to eject enough but not too much excess fluid in the system?

From forum posts I gather many folks struggle with that.

The Hope manual says to just open the bleed nipple and let the caliper retract without further details:

"Open the bleed nipple a 1/4 turn to allow the pistons to retract into the caliper. The pistons are spring loaded and should return on their own but may require manually pressing back."

The Hope FAQs go into much more detail:

"When the reservoir cap is screwed completely tightened, the caliper pistons may be extended such that the pads are touching. In order to open the pads, loosen the bleed nipple screw until just a drop of fluid is released from the bleed tube (this is why we left the hose still attached). You may have to turn the adjuster knob clockwise just a little bit to get enough fluid to come out. Do this only until you have enough clearance between the pads to put the wheel/rotor back in place to run drag free."

Is this the way to go or is there a better method?

5) Can I install a 6 mm braided Hope hose with the original hydraulic fittings by installing the 6 mm olive right around the outer plastic skin and then screw it together?

I originally came across this youtuber who seems to know a lot about Hope brakes who does it exactly like that (

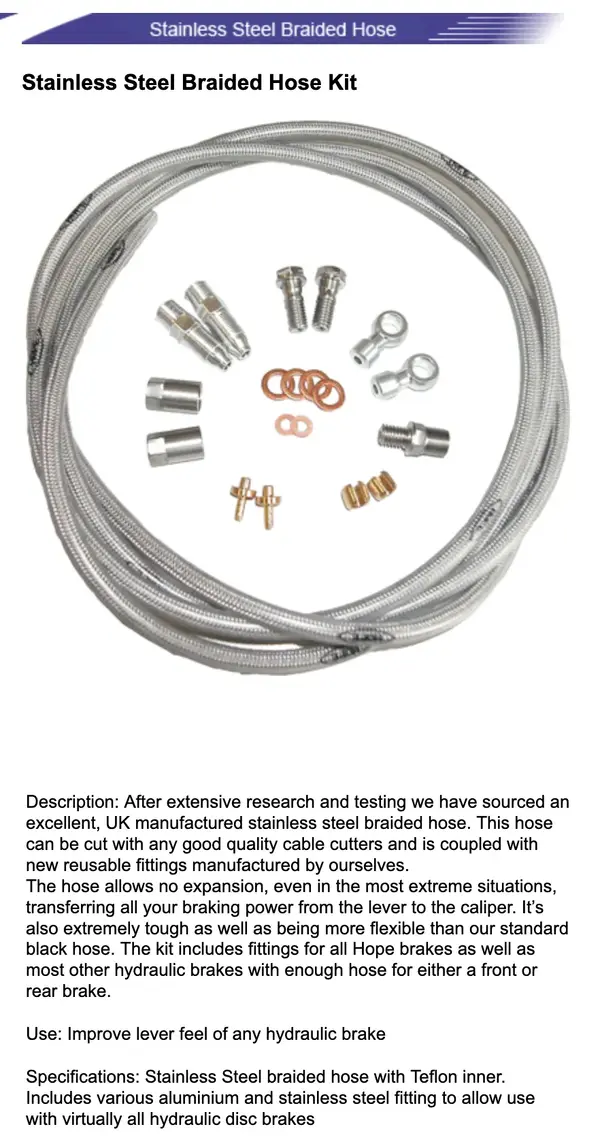

But then I found that when Hope came out with their own braided hoses they sold these together with the then new 5 mm olive and new 5mm hydraulic fittings right from the start:

For this, I figure one has to strip the outer plastic skin before installing the 5 mm olive right on the metal braids, otherwise the smaller olive won't fit.

Any experiences whether one method (plus parts) is better than the other? I'd favor less tinkering so would be happy to skip skinning the hose first.

6) Is there a way to get rid of the lateral play of the Pro levers?

Every set of Pro levers I got has a little play laterally when squeezing the lever, right before I feel that the lever actually presses on the piston. While with some levers I found some play between the lever and the brass barrel in the middle (1 and 12 on the diagram https://www.hopetech.com/_repository/1/documents/ClosedProleverExpview-1.pdf), all levers seem to have some play between the round end of the adjuster screw and the top of the piston (9 and 4).

Any way to get rid of that or is there even another reason for this play?

7) Should I use the "new" upper piston seal or source it from the Sport version?

The upper piston seal currently sold by hope doesn't really look like the one installed in my levers.

The new upper seal sold by Hope closely resembles the lower one, a bit like a plate with some hollow section at the bottom (sorry for my English - can't really describe it accurately): https://www.sjscycles.co.uk/brake-l...der-seal-kit-complete-pro-hbspc59pro/?geoc=AT

In the two levers I already disassembled though, the upper one has a ring shape, as pictured in the Hope diagram (7 in the diagram https://www.hopetech.com/_repository/1/documents/ClosedProleverExpview-1.pdf).

Interestingly, it looks more or less exactly like the upper piston seal still sold by Hope for the Sport levers https://www.sjscycles.co.uk/brake-l...seal-kit-complete-sport-hbspc59sport/?geoc=AT

Any experience if one of these is better to install?